Security and surface decoration metallised foil supplier Kurz will soon be showcasing a range of new solutions at the upcoming virtual.drupa tradeshow.

The company provided a sneak peek into the technologies that will be on show in the areas of hot stamping, cold transfer, digital transfer, workflow solutions, brand protection and sustainability.

Within the digital transfer space, Kurz will be launching a new Steinemann DM-Maxliner press. The technology follows Kurz’s acquisition of the print finishing division of Switzerland-based Steinemann Technology in July 2019.

The Steinemann DM-Maxliner press is a digital finishing machine that produces 7000 sheets per hour.

“It runs superb definitions and printing quality, which is required in the industry. It simultaneously does the metal effect and spot varnishing – it’s all done in the first run. We can also ramp up this machine for a new job, including rendering, within minutes,” Kurz business area senior vice-president of industrial and application Markus Hoffmann said.

“It is an unmatched technology and we are looking forward to having you see this press in action in person.”

The company is also launching an extension for narrow-web printing lines – the DM-Jetliner.

“The DM-Jetliner offers quality in terms of fine details. Once it is integrated inline, it delivers enormous savings as finishing is included, and works at fast speeds so you’re not reducing any time in the finishing process,” Hoffmann mentioned.

Within the cold transfer space, which the company identified is one of the biggest areas of growth for the business, it will launch the KPS SX+, an inline technology that can be easily integrated into offset sheetfed printing or in narrow-web flexo printing.

The KPS SX+ has enhanced capabilities to offer improved super high gloss, more defined details and better coverage. It also enables reduced press downtime and has one of the widest working windows in the industry.

Hoffmann said the SX+ is designed to replace all existing products Kurz has in the cold transfer space.

“The SX+ is a new product that delivers better quality, at a lower cost and higher flexibility in terms of time to market,” he said.

As for the hot stamping sector, it has developed an all-in-one foil, the Luxor/Alufin MSU, which has the flexibility to be used in the creation of rough surfaces, coated surfaces, OPP laminated surfaces, and UV coated surfaces.

“It is designed to go on a lot of a variety of different surfaces and substrates, delivering to the industry the advantages of having one-for-all. As a consequence, a customer is also able to significantly reduce the amount of stock at their premises. With reduced complexity, customers can also be more efficient,” Hoffmann said.

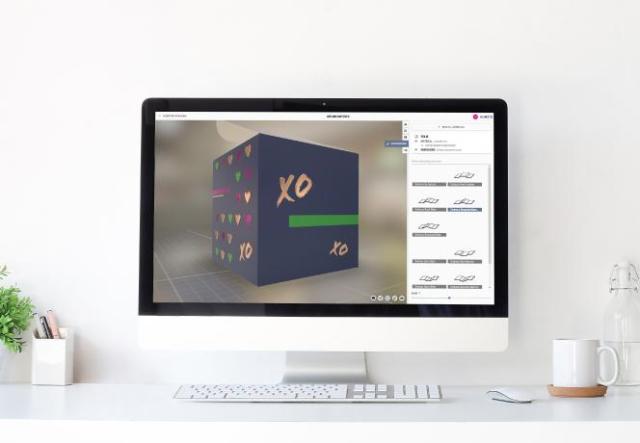

Kurz has also branched out within the workflow solutions sector, which the company identified as a new area of opportunity, with the upcoming launch of Dreamcomposer.

Dreamcomposer is a software for brand owners and designers. It shows users what the quality of the finished solutions will look like under different angles, on different packaging options and under different lightings.

Within the brand protection space, Kurz is working on a security and embellishment solution.

“Such types of solutions are increasingly in demand as there are a lot of counterfeiting happening worldwide. The demand for unique security, with a unique finish, which also delivers embellishment and brand enhancement is available from Kurz,” Hoffmann said.

Hoffmann also spoke about the company’s sustainability initiatives, saying that it has introduced PET recycling technology which is in beta testing.

Last year, Kurz came out in support of the drupa international printing and packaging trade show saying it is an important platform for the industry. The company will be releasing more details on the new launches at the virtual tradeshow.