With today’s brands and packaging suppliers facing a catalogue of potentially crippling challenges, Esko has developed its latest software innovations to make it easier for people and processes to connect, to automate operations and to drive operational improvements.

“From the energy crisis and the erosion of margins to material shortages and labour and skills deficits, we know there are many significant challenges for businesses today,” Esko director of marketing, industry relations and strategy Jan De Roeck said.

“The role of technology and innovation is key in surmounting these challenges. It is now imperative that companies review their current business operations and identify areas where they can make meaningful improvements and drive operational efficiencies in order that they not only survive but thrive.”

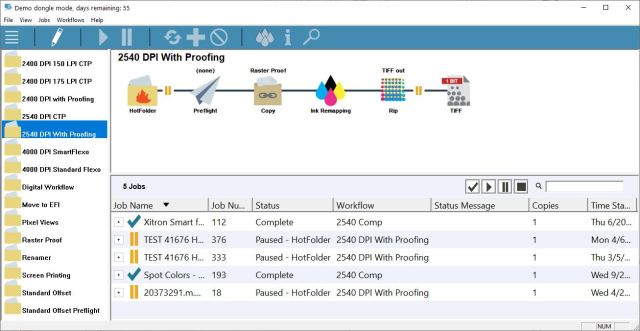

It is in this climate that Esko has developed its software version 22.11, bringing to market new technological developments that will advance the industry, helping businesses form a foundation to identify waste, mitigate risk and optimise opportunity.

Esko Release 22.11 includes a host of new features, including:

• Dynamic Subscriptions – a new, cloud-based licensing model for on-premise applications that simplifies global management and distribution of licenses across all sites

• ArtPro+ GMG OpenColor Connector – enabling smarter working with simplified colour management across systems, with state-of-the-art visualization and automation tools bringing new levels of colour predictability and efficiency across the workflow

• Greater flexo automation – with new PlateID automatic placement and the introduction of nested merging in Flexo Engine, delivering more automation and improved efficiency in the plate room

• Automated workflow improvements – new multi-MIS support in Automation Engine SaaS and new configuration tools in WebCenter to improve user experience

• New FEFCO standards as parametric tools in ArtiosCAD – Esko is the first to bring to market the new FEFCO (the European Federation of Corrugated Board Manufacturers) design style standards as parametric tools, in its structural design software

• Integrated Tilia Labs Artificial Intelligence – leverage Artificial Intelligence through Esko Automation Engine; rethink the planning and imposition process and unlock productivity improvements with a seamless interface between prepress data and production data.

“Our key focus with this latest software release is to deliver technology that makes it easier for packaging companies to connect its people and processes, to access data, automate operations and to drive operational efficiency,” De Roeck said.

“Our new Dynamic Subscriptions, for example, are assigned to a group of individuals, rather than one single user. When logging on, each user – wherever they may be based – is simply assigned an available license, provided there are licenses available in the group. When the user ends their session, this license is immediately released back to the group, enabling continuous, uninterrupted access and potentially 24/7 operation without the excessive costs of individual licenses for all.

“Similarly, we know the manual reseparation of images and artwork to match brands’ colour accuracy demands can be a laborious and error-prone process.

“By automating the reseparation using GMG OpenColor technology – via the new unique integration with Esko ArtPro+ in software version 22.11 – prepress professionals can now accurately visualise colour in before-and-after states and assess colour deviations on-screen with precise Delta E readouts.”

Following the recent acquisition of Tilia Labs, Esko is also delivering on the need of brand owners and converters to connect and integrate the entire value chain through upstream digitalisation.

“Tilia Labs’ tilia Phoenix solution has now been integrated with Esko Automation Engine,” De Roeck said.

“Featuring intelligent algorithms for sheet layout, estimation and planning, this underlines our commitment to delivering integrated software and hardware solutions that accelerate the go-to-market process for consumer packaged goods. We are filling the gap between converters and brand owners by providing tools to help the converters do the job better, faster and more efficiently.”