With the 2025 National Packaging Targets and 2030 Food Waste Targets looping closer, now is the time to rethink and redesign food and beverage packaging, according to a group of panellists who spoke at the recent FoodTech Qld event.

Innovation and design thinking were covered in this session, along with details on how to embed circular design practices into packaging design processes and to better understand what innovations are standing out on shelf in the region.

Close the Loop Group CEO Joe Foster said design innovation not only helps a business stay ahead of its competitors and resonate with consumers, but also that these innovative and intuitive packs are more sustainable and offer a much lower environmental impact to previous designs.

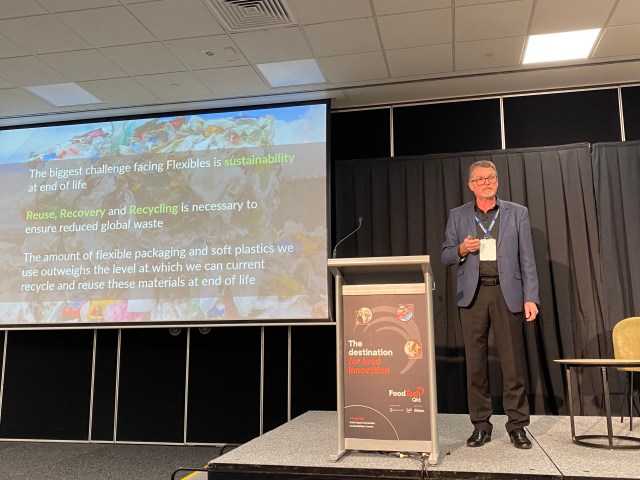

“The biggest challenge we’ve got within recyclability is flexible packaging itself. And when we talk about the challenge around recyclability of flexible packaging, it is its end of life – the ability to try and reuse, recover, and essentially repurpose packaging material,” he said.

“With the amount of soft plastic out there, the supply is certainly greater than the demand which means there’s plenty of soft plastic currently going to landfill. Until we find a solution for the end of life of soft plastics – something that’s going to be suitable for direct contact with food – that challenge will be there for certainly longer than 2025.

“And the solution must be really around the circular economy – we’ve got to try and think about ways to put it back into the true circular economy.

“We’re talking about reuse, collection, and redistribution back into the actual packaging network itself. This is where we’re going to have to start working together. Industry, brand owners, supermarkets, retail chains, and the government, need to all come together because it’s not just one solution that will work across all.”

Pact Packaging innovation manager Anhely Millán addressed how innovation drives the circular economy and what Pact Packaging does to help its customers to achieve national and global packaging targets.

She identified some findings from a recent global study commissioned by Pact, which found that consumers are driving the change towards a more sustainable future – especially following COVID.

“One in four consumers support brands with social causes, 34 per cent of them use brands that support environmentally-friendly packaging, 44 per cent rate a company’s ethical supply chain as a factor nice to have and 30 per cent seek information on packaging,” she said.

“With consumers wanting to reduce their personal footprints, there needs to be an increased public awareness about the circular economy and businesses need to offer brand transparency, public education, endorse community projects and invest in R&D.

“Recycled content and recyclable materials are no longer enough; we need to work on preventing waste from being created. So, co-operation and collaboration is also definitely key to achieve all the targets and everything needed for best practices.

“Failure to act will be detrimental to the future success of brands. I really do encourage you to start thinking of how you’re going to achieve your 2025 targets – at least to start on something however small now and then progressively move to a more sustainable supply chain solution.”

Brookfarm head of procurement Sally Carter showcased the company’s award-winning packaging design that has been recognised locally and globally for standing out.

Carter spoke about how the design of Brookfarm’s curbside recyclable, high barrier stand up pouch – created in conjunction with Close the Loop Group – offers significant shifts in materials, reductions in environmental impacts, is light weighted, and includes recycled content.

“From a business perspective, Brookfarm adopted sustainable practices early on – like using solar power within our facility and regeneration of the farm,” she said.

“However, we had a challenge on the consumer side five years ago around what we could do as a business to have a product that can either be biodegradable, compostable, or recyclable and driven through our customers.

“At the same time, we needed to have a premium product that ensures the right shelf life of the product, that can be manufactured with the right speed and efficiency, as well as providing a print quality on a recyclable packaging.”

The final solution created allows consumers to transform the empty, 100 per cent Polyethylene packaging into a 3D shape suitable for their home recycling bin and enabling it to be recycled.

As it can be rolled into a cylindrical 3D shape, it can be separated and sorted into the plastics stream, and therefore recycled with all the other plastic materials.

“We’ve had positive feedback from our consumers around the ability to recycle the packaging as well as encouraging us to take the leap of faith and actually expanded across our entire retail range,” Carter added.

As such, she said that Brookfarm will be transitioning the packaging of its entire retail range to this format by the end of the year.

Cyclpac managing director Edward Whitehead spoke about the solution it created for Melbourne Coffee, which won the PIDA Sustainable Packaging Design of the Year (Recycle) gold award in 2021.

The solution is a 100 per cent recyclable bag from a single source polymer group with a technical barrier to oxygen and moisture for the coffee brand. With the knowledge this will contribute to the ease of recycling, it is fully aligned with the European strategy for soft plastics recycling and a circular economy.

“As packaging designers, we have an overwhelming responsibility to food safety and the preservation of food. So whatever you do in designing packaging or putting it together, make sure it serves its primary purpose, which is to arrive to the client in good condition,” Whitehead said.

“And if you can do that and extend the shelf life, which should be a big focus of your solution, you must do it. One extra day of shelf life is massive for a retailer so this is something we should focus on.

“With Melbourne Coffee, we created a solution using a limited colour pallet to keep the print coverage to a minimum to support ‘end of life’ recycling but without compromise to design aesthetic and appeal. Keeping ink coverage low and using a white substrate to support artwork reduces inputs and supports ease of recycling and material composition.

“We also had on the package critical ‘on packaging’ calls to action, combined with clear signposting of appropriate recycling streams in both Australia and Europe provided through ARL, OPRL and Red Cycle.

“Consumers need guidance about recycling or disposal, and clear labelling schemes support this process even if it means we don’t have it our system yet. That doesn’t mean we shouldn’t design our products with it.”

Planet Protector Packaging sustainability manager Lars Ljung spoke about how the company is on a mission to eliminate polystyrene from supply chains.

“Polystyrene has been in the industry for over 70 years. It’s very difficult to recycle and has basically become a bit of a ‘problem child’ in the packaging industry. Some of the other issues with polystyrene is that it is expensive to store because it does not come flat packed. Government legislation around the world is moving to phase this material out. And if this product is stored in warehouses, they face increased insurance premiums because it is a flammable material,” he said.

In response to the challenges, Planet Protector created Woolpack, a recyclable or compostable liner with enclosed wool that is micro-perforated to allow the wool fibres to breathe and create a natural cooling system for products in a box or pouch.

“The wool that we use is 100 per cent biodegradable – there is no additives or adhesives used to make the product and it comes flat-packed to save space. Woolpack liners can be reused multiple times, often more times than poly boxes which easily crush and break apart in rough transport.

“Our Woolpack solutions have been tested and proven to outperform both polystyrene and alternative packaging. Clients have also found a reduced need for refrigerant as opposed to polystyrene. This saves resources and reduces freight costs.

“From fresh foods to seafood, pharmaceuticals, to chocolate, Woolpack has been proven to keep contents below 5°C for well over 24 hours and between 2°C and 8°C for 72 hours and beyond.”