Leonhard Kurz has taken Labelexpo visitors to the future of thermal transfer by presenting the (R)Evolution range with all design and security aspects.

The new range offers brilliant colours, holographic effects and effective protection against counterfeiting.

The company is also presenting various solutions from the areas of hot stamping, cold transfer, digital embellishment and sustainability.

Labelexpo visitors can also see the latest digital embellishment systems, such as the Kurz DM-Uniliner 2D and the DM-Uniliner 3D from its subsidiary Steinemann DPE.

The Distorun module, also on show, offers a material-saving cold transfer and enables efficient single-image application by providing more flexibility. Cold transfer serves as a substitute for laminates, and thanks to innovative Kurz solutions, it has become even more sustainable and efficient, among other things, by reducing the carrier thickness to 6µm.

Kurz subsidiary H + M is showing effects for label finishing achievable with its stamp technology and the new solutions for brand protection and product safety. These include ValiGate from Scribos and various security solutions from TrustConcept.

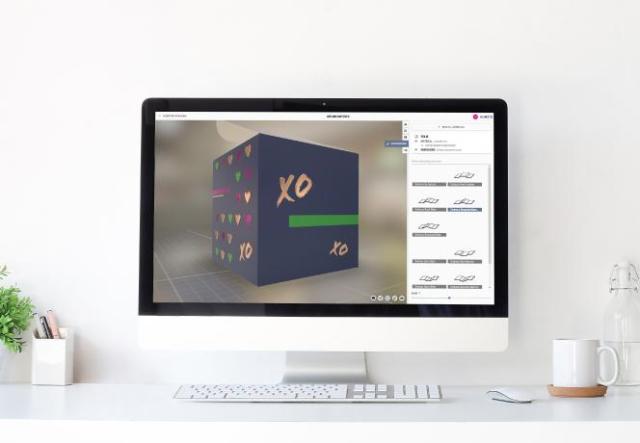

Kurz has also introduced a new cutting-edge digital metallisation capability based on the recently launched Xeikon Titon toner technology. The new technology integrates Kurz Digital Metal with the Xeikon TX500 digital press to produce premium labels.

This unique one-step embellishment method offers a versatile, low-cost alternative to traditional hot foiling, and notably, it is the first food-safe digital metallisation solution on the market.

Xeikon director of solution design Jeroen Van Bauwel said, “Printers are constantly searching for better ways to add value to the labels they produce for their customers. Meanwhile, brand owners are looking to maximise shelf standout with brilliant designs that shine and sparkle. They also want to get to market faster, at a lower cost.

“This new digital metallisation process offers unlimited possibilities for production of high-quality, highly embellished labels with Xeikon’s Titon toner technology. Metal effects are created in one process without needing special adaptations to the print file. And since it’s all done inline, no highly skilled operator intervention or re-registration are needed. It’s as simple as adding another colour.”

With the full freedom of digital printing, including orders of just one label, the new digital metallisation process can be used to add both solid areas and very small details (in positive and negative) in 1200 dpi resolution, anywhere in the design.

Each label can be different with variable elements in print and metallisation matching each other.