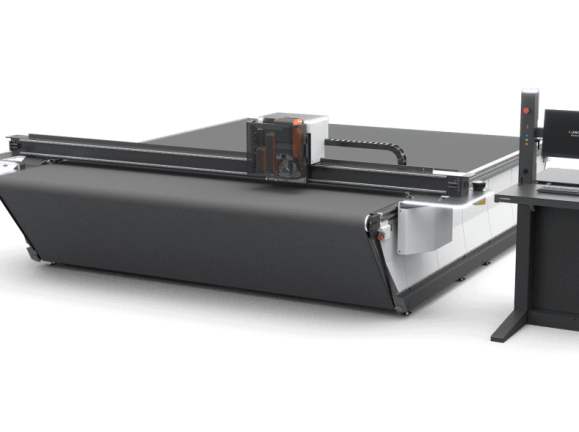

Kongsberg Precision Cutting Systems (Kongsberg PCS) unveiled its new digital cutting platform, the Kongsberg Ultimate. Poised to transform the corrugated production industry, it offers impressive levels of productivity, precision and safety.

With its new, innovative drive technology, an impressive acceleration rate of up to 2.74G and a remarkable cutting speed of 168 meters per minute, the Kongsberg Ultimate is a testament to Kongsberg PCS’s commitment to developing the latest technology.

“Engineered with our deep understanding of corrugated and display converters’ needs for precision, the Kongsberg Ultimate promises to redefine standards and usher in a new era of productivity and innovation, delivering a fast return on investment for convertors of corrugated board,” said Kongsberg PCS president and CEO, Stuart Fox. “Enhancing operations and providing a significant competitive advantage, the platform sets a new industry benchmark and is set to drive the future of corrugated production for years to come.”

Incorporating six core values in the design, the Kongsberg Ultimate represents a quantum leap forward in technology, directly addressing the unique challenges faced by corrugated converters involved in continuous high volume multi-batch production.

“With corrugated converters around the world under increasing pressure to produce better, faster, safer and more efficiently to meet the demands of the global market, we have underlined our commitment to deliver a solution that has been engineered for precision and built for productivity,” added Stuart.

“Businesses seeking to elevate their operations need look no further than the Kongsberg Ultimate.”

Kongsberg Ultimate Core Values:

Unlocking the Kongsberg Ultimate’s performance capabilities

Productivity: With its new drive and beam design, the Kongsberg Ultimate defines the next generation of design and performance. This leads to significant productivity gains and return on investment for users.

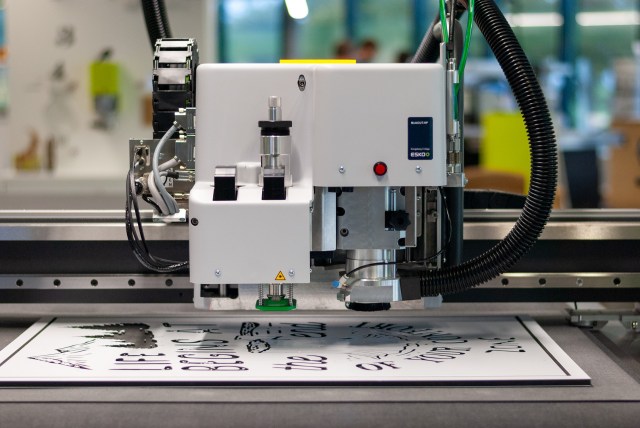

Precision: With its meticulously designed custom carbon fiber beam, the Kongsberg Ultimate ensures unparalleled stiffness and consistently applies a 50kg downforce. The tool head camera further elevates its precision, making every cut align perfectly with the highest industry standards.

Safety: The Kongsberg Smartzone safety solution is an innovative proximity-driven dual-zone system crafted to blend safety and efficiency seamlessly. Furthermore, the intuitive LED lighting ensures machine status is crystal clear, ensuring a safe and productive environment.

Uptime: With new self-diagnostics and remote operator alerts, combined with the application of proven robust technologies from other high-demand industrial fields, the Kongsberg Ultimate is designed to deliver the highest uptime to maximize utilisation.

User Experience: Operators are at the heart of every production. Keeping this in mind, the Kongsberg Ultimate boasts the intuitive IPC 3.0 interface with touchscreen to enhance the operator experience, with easily accessible buttons on the machine making every task seamless and user-centric.

Sustainability: The Kongsberg Ultimate incorporates greater use of recycled, readily recycled and other materials with less environmental impact, demonstrating that Kongsberg PCS takes its commitment to a greener future seriously.

Unveiling the innovative new table at the company’s headquarters in Gent, Belgium, Fox said: “We have worked creatively to ensure that our future is built upon manufacturing equipment that our customers and team can be proud of. The Kongsberg Ultimate is not just an evolution but a leap forward in corrugated production technology and a commitment to the corrugated industry for the future.

“This remarkable achievement reaffirms Kongsberg PCS’s position as an industry leader and underlines our dedication to delivering innovations that empower businesses to thrive in an ever-evolving marketplace,” he added.