Trimatt Systems cuts its own path through digital printing market.

Since its inception in 2005, Trimatt Systems has grown a portfolio of innovative solutions for the printing, packaging and Smartcard industries.

The company has carved out an enviable reputation for producing high quality machinery and technology that continually exceeds the expectations of its customers. Trimatt’s custom-built machines have helped drive the success of a diverse range of businesses that includes commercial printers, label printers, packaging companies and coffee roasters.

Matt Johnson, founder and director of Trimatt Systems, has helmed the company throughout its journey. With a focus on staying abreast of industry trends, Trimatt develops solutions with its customers’ business needs in mind.

However, substantial growth and innovation have not changed Matt’s philosophy that customer support is paramount. He says, “It does not matter whether we are providing solutions to a large company or a small or medium sized business, local or international, we take a serious approach to consulting with you to find the right solution for your requirements. As your business grows, we continue to support you.

“We understand that as the business environment continually evolves, you need to adapt your business accordingly. Trimatt’s ongoing focus on excellence helps our customer-focused solutions exceed the expectations of our clients across several sectors.”

Recently, and particularly as a result of the post-pandemic economy, consumer attitudes have shifted in favour of purchasing locally manufactured printed products over formerly cheaper imports. This appreciation of the merit in shorter turnaround times has accelerated the already rapid growth of on demand short run digital printing. Trimatt’s customers have benefited from the company’s leadership in this area and have gained access to solutions like the award-winning Trimatt ColourStar AQ, which targets fast turnaround short to medium run printing.

Matt says, “We are thrilled when we can help our customers adapt quickly to an ever-changing marketplace. The ColourStar AQ is an example of how Trimatt technology can help you free up space and time while ensuring your customers keep up with their own deadlines.”

Recent success

Over the past two years, Trimatt has consolidated its earlier successes, confirming its reputation as a leading manufacturer and supplier of high quality machinery. The company has also positioned itself as a preferred supplier in the sustainable packaging industry.

At the 2022 Australian Packaging and Processing Machinery Association (APPMA) Awards of Excellence, Trimatt earned the prestigious title of Machinery Manufacturer SME of the Year. This award recognises Trimatt’s absolute commitment to innovation and the success of its CardLine 7000.

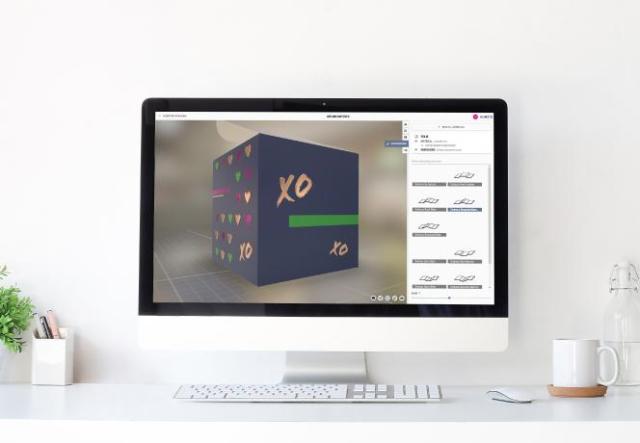

Trimatt also introduced the ColourStar AQ range, an all-in-one, customisable, industrial digital colour printing solution designed for making in-house package printing fast, economic, and profitable.

The company sees the ColourStar AQ V redefining sustainable printing for paper and cardboard packaging, placing the profit in food and drink manufacturers’ hands by providing a versatile and economical solution for eco-friendly packaging needs. Applications include coffee bags, retail paper bags, packing boxes, and takeaway food packaging. Trimatt offers an integration module (IM), a mid-range entry-level desktop conveyor model (LT), and the most popular Versatile (V) model.

After taking on a starring role for the company at PacPrint, the Trimatt ColourStar AQ took out the Melbourne International Coffee Expo (MICE) 2023 Product Innovation Award.

Trimatt continues to design and innovate across the board. Recent developments include:

Innovative Auto Feeder: The development of the pick-and-place paper Handled Bag Auto Feeder has helped streamline the packaging process while improving accuracy and efficiency.

CupPro 600: Trimatt revealed the CupPro 600 at this year’s FoodPro Expo. This sustainable cup printer offers an environmentally friendly and economical option for custom cup printing.

Magazine Paper Wrap Machine:

Trimatt is installing the first magazine paper wrap machine, the Trimatt G-25, to a leading Australian multi magazine publisher.

Trimatt FoldLine 9000: Australian manufacturers continue to compete effectively in supplying large-scale recyclable packaging thanks to solutions like the Trimatt FoldLine 9000 for FMCG food tray sleeves.

Trimatt’s sustainable packaging solutions are not confined to the present but are tailored to meet the requirements of projected future markets across multiple industries.

Mel McFarlane, marketing coordinator at Trimatt, points out, “An astounding 80 per cent of Trimatt’s customers return after their initial machinery success to order further complementary solutions.

“The generation of profit on labour from their first investment positions them to invest further in automation, again propelling their competitive success. We partner with companies that understand that, in this global economy, the best time for automation and in-house manufacturing is always now.”

Matt concludes, “It is with great pride that we reflect on the past few years and how we have had the opportunity to provide our customers with cutting-edge technology and machinery that helps their business.”