Managing director Graph-Pak, Tom Ralph (left) with Dayne Nankervis, CEO, CMYKhub.

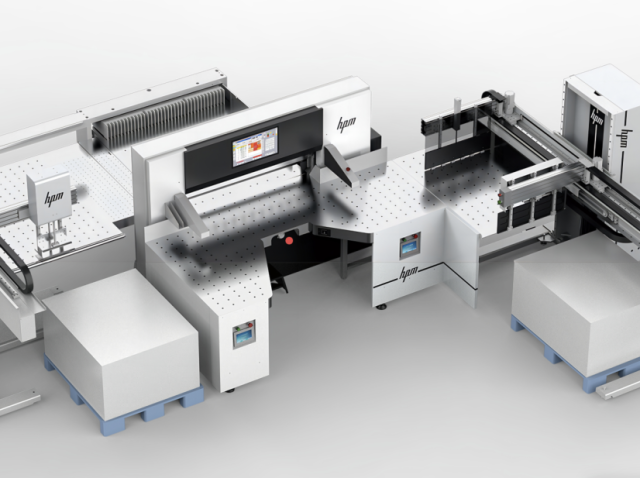

Progressive print business, CMYKhub, has its eye on the future and furthered its business capability with its latest purchase of Graph-Pak’s Boxway Fitsize 2500, setting up an “Amazon-like’ business model.

The Boxway Fitsize 2500 produces custom-size corrugated boxes. It allows CMYKhub to produce boxes when required, reducing box warehouse management by producing fit-sized boxes at the touch of a screen. See Boxway Fitsize 2500 in action in this video HERE.

Propack spoke with managing director Graph-Pak, Tom Ralph at the APPMA Awards at APPEX Melbourne.

“The Boxway FitSize 2500 is the way of the future for on-demand boxes. Companies can no longer afford to have tons and tons of pre-purchased boxes sitting around on racks in a warehouse.

Ralph says a minimum order might be 2000 boxes, which ties up cash flow. He says with this product, people can enter a few numbers into a machine and out comes the box.

“The reinforced corners eliminate the need for other substrates and result in less damage. This machine is ideal for companies replicating the Amazon model of just-in-time shipping and is very affordable at around $160,000.

“It has many features available, including a weigh scale, integrated printer, and automatic labeller—it can even scan a barcode and call a courier when the job is done,” explains Ralph.

At APPEX, the CMYKhub team said it was excited about the positive impact the Boxway Fitsize 2500 will have on the business.

“We have bought the Boxway FitSize 2500 from Graph-Pak to help us create shipping boxes in whatever size we require. It is well priced and really easy to use,” said Alan Nankervis from CMYKhub.

“The software is great and you can custom-build the box using the proprietary software – we love it.

“Adding a box maker gives us more flexibility to package our print more safely and more efficiently. This eliminates wasted space and also prevents damage in freight which has been a bit of an issue for us over the last few years.

“The delivery of wide format print can result in boxes being dropped on corners which damages the customers’ order. With the box maker, we can add custom air gaps to ensure that we have 100 per cent fulfilment of orders and less reprints out the door.

“At the moment, we are wrapping our products in bubble wrap manually on the factory floor. We want to get rid of the bubble wrap by using a box that has an air gap. This is really going to save money and also save the environment which is where everyone wants to be.

“We love working with Tom and the team from Graph-Pak. We have bought a lot of machinery from Tom and you couldn’t ask for a better company to deal with. His service is second to none and his support is excellent.

“This is going to be a very important piece of machinery for us. We will install this into our wide format facility at Preston. Hopefully this is first of a few purchases and we can add more of these around the country.

Nankervis confirmed he first saw Tom Ralph demonstrating the Boxway FitSize 2500 at a previous exhibition.

“We have spent a lot of time looking at the machine as well as working with the Boxway team online providing us with demonstrations of the software. They also have a lot of other gear that we would like to add like scanners to make the box machine fully automated, Nankervis said.

Ralph said the sale of the Boxway FitSize 2500 was not just another machinery transaction, as CMYKhub represents more than just a customer.

“It is always a pleasure to work with the gentlemen from CMYKhub. They are extremely experienced businessman – they know what they want, and they negotiate fairly hard – but at the end of the day, they are one of those customers that also become a partner, so doing business is always a great experience, Ralph said.

“The Boxway FitSize 2500 is the way of the future for on-demand boxes. Companies can no longer afford to have tons and tons of pre-purchased boxes sitting around on racks in a warehouse. A minimum order might be 2000 boxes and it ties up cashflow. With this product, people can enter a few numbers into a machine and out comes the box.

“This eliminates the need for other substrates and results in less damage due to the reinforced corners. This is an ideal machine for companies replicating the Amazon model of just in time shipping and is very affordable for around $160,000. There are so many features available with this machine including a weigh scale, integrated printer, automatic labeller – it can even scan a barcode and call a courier when the job is done.

“We started working with CMYKhub in 2006 when they purchased an Autobond laminator from me and they ended up with five of them. They then went on to buy a smaller D&K commercial laminator from us and have bought multiples of these since as well.

“As they have progressed, they have gone into folding carton and bought a number of products from me including rotary die cutters, folder box gluers and ecommerce taping machines. A lot of the counting equipment they have has been purchased through us. Overall it has been a very happy relationship the whole way through,” Ralph said.

For more information on the Boxway click HERE