Cardbox Packaging, an international manufacturer of folding cartons, has installed Heidelberg solutions in its site expansion.

The former, which operates production sites in Austria (Wolfsberg and Pinkafeld) and the Czech Republic (Zádveřice), most recently set up a site in the US (Pittston), which it partnered with Heidelberg for.

As part of the deal, Heidelberg has provided Cardbox Packaging with extensive consulting services and an overall solution package comprising machines, service, and consumables.

The goal of Cardbox Packaging is to expand the business through the addition of new sites and to give each location a sustainable orientation. From the beginning, the company has counted on strategic partners for this purpose, according to Cardbox Packaging CEO Roland Schöberl.

“One of the main reasons for the success of our expansion strategy is that we brought the right partners on board, Greiner Packaging and Heidelberg. Both are innovative and customer-oriented – and that’s how we see ourselves too,” he said.

The joint venture with Greiner Packaging, a provider of plastic packaging, was instrumental in Cardbox Packaging paving its way into the North American market.

“When another major customer, a brand owner based in Europe, indicated its intention to have its folding cartons produced at Cardbox Packaging in the future, the move across the Atlantic was a foregone conclusion,” Schöberl said.

“However, the market in the US works differently to Europe in all regards, whether consumers, clients, or suppliers. Cardbox Packaging therefore intensified its collaboration with Heidelberg as a global partner.”

During the move into the new building, Heidelberg supplied the equipment and established a lean production system with short supply chains and an efficient material flow.

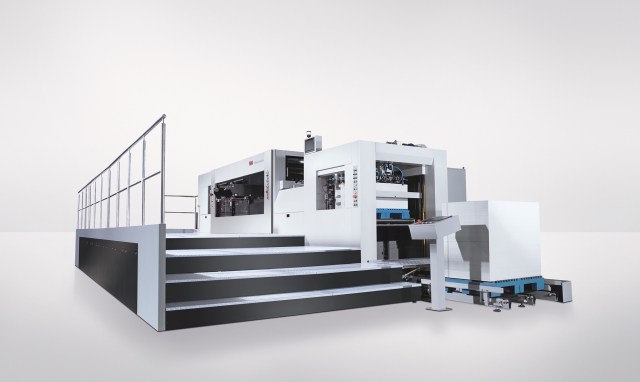

A Suprasetter CtP system was installed for imaging in prepress, while a Speedmaster XL 106 six-color press runs with double coating and full logistics in the pressroom. The sheets are finished with the Promatrix CSB die cutter and the Diana Easy folder gluer in postpress.

According to Cardbox Packaging, the Prinect Production Manager workflow provides for integrating these processes.

“With the 36 Plus service agreement, we’re buying ourselves production reliability. We know from experience that it’s definitely worth it, because it helps us to avoid unscheduled downtimes,” Schöberl said.

He added that Cardbox Packaging also benefits from a streamlined supply chain and much lower complexity.

“Instead of negotiating with several suppliers, we get everything from one source, from Heidelberg. This makes a lot of things easier. We save process costs, and the reduction of the workload in day-to-day business frees us up to focus on key topics such as new offerings for our customers,” he said.

Around 20 employees work at the Pittston site, producing packaging primarily for brand manufacturers in the confectionery, food and cosmetics industries.

Cardbox Packaging CEO Klaus Hockl said the company plans for further growth.

“We know that our success depends on people to a large extent – on our employees and our partners. Heidelberg is actively driving digital topics like big data and the Internet of Things. This gives us many opportunities to enhance our performance and grow further, without having to make new investments,” he said.

Cardbox Packaging has also installed Heidelberg equipment at its Austrian sites, with a Speedmaster XL 106-6+L with full logistics in operation in Wolfsberg, and a Diana Pro as well as a Promatrix CSB in Pinkafeld.