In 2023, Durst had a fantastic year locally and globally – sales were strong across the board with labels and flexible packaging a standout category.

We noticed a number of key trends including the popularity of our hybrid solution with our global business partner Omet at Labelexpo as well as the trend of commercial printers entering the labels and packaging category, and in some instances labels and packaging companies crossing back over into commercial printing.

Label converters are demanding for more integration and at Durst we are looking to be able to deliver a less confused go-to-market strategy in 2024 with our hybrid solutions. Local converters are always looking to add inkjet to their portfolio as this is the key sector that requires a hybrid solution. Some converters work with an inline or nearline solution, but the high production dyed-in-the-wool label converters require a hybrid solution.

Durst has always had strong relationships with converter manufacturers, especially Omet for hybrid solutions, however we identified the need to streamline the go-to-market strategy globally.

At Labelexpo in Brussels, it was confirmed that Durst and Omet hybrid solutions would be re-sold by Durst subsidiaries in every region including Australia and New Zealand and the entire Oceania region.

We are not seeing to criticise the great job that the existing Omet distributors have done and will continue to do in the local market. But the good news is that Durst Oceania can now sell the X-Jet – as well as new and exciting products that will be unveiled at Drupa in May and June – as full hybrid solutions with full Durst integration.

The benefit for traditional label converters is they’ve always worked with hybrid solutions – a complete line will consist of an unwinder, a pretreatment maybe post-treatment, maybe a flexo unit, maybe an embellishment unit and then right to the end with a converting unit slitting and finishing the label.

With the Omet hybrid solution, we can drop in a Durst high speed inkjet solution within that mix, and then the label converters can use it with the inkjet or without the inkjet as they can bypass inkjet and have the option to use some of the flexo stations as the whole unit is upgradeable.

If they have two pre-flexo and three post-flexo units, they can use it as just a standalone flexo station or a hybrid solution. Therefore, it gives them the comfort to know what they know with the bonus of having the latest inkjet technology.

We have also seen a continuous trend with the demarcations to be broken down between commercial print, large format print, label converting and packaging. If you’ve got a machine that can print you’ve got a machine that can deliver solutions.

Run lengths are compressing, but the volumes are still there. We have noticed that customers or end users want them to be delivered in smaller batches. We have customers now printing thin card on the label press – not just self-adhesive – for actual packaging purposes, as well as many other cross- fertilisation printing techniques.

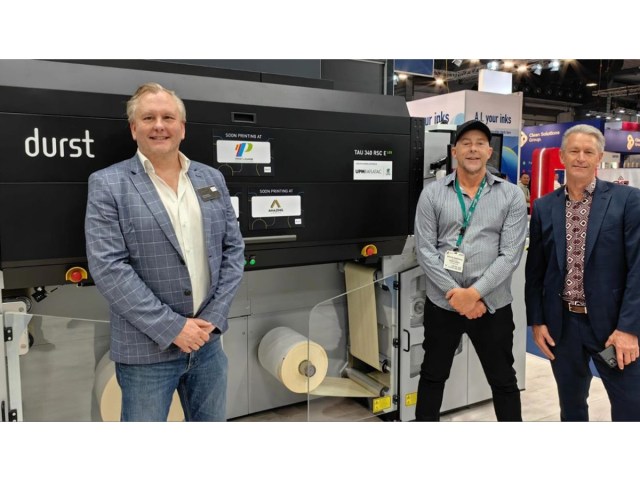

With the Durst RSC-E solution – you have an immediate turnkey solution. You can buy a laser finisher and a business that has never actually produced labels before can produce high quality labels in-house straight away and satisfy a need that their customers have – creating a one stop shop. What is also interesting – we have also started to see label converters, who have been exposed to the Durst wide format technology saying to us – ‘Hey, maybe I can do this as well’. So wide format is now not only a possible threat to the traditional label converters, it’s also an opportunity.

Labelexpo 2023 was a digital inkjet show. Everybody was talking about digital inkjet because of the robustness of the machines and because the ease of use. Digital inkjet also delivers a massive reduction in wastage as need to produce products in the most sustainable way. We are reducing the energy consumption of the machines by being the first inkjet producer to introduce LED curing delivering a massive reduction in the power consumption of the press.

We’re also removing all the TCOs from our chemistry so that our inks will be the most sustainable and most environmentally friendly they can be while remaining best in class and without compromising on performance.

Durst is continuing its investment in the labels and packaging category. We are one company who are growing that sector in many different directions. There is some incredible technology to be announced within this category and across the portfolio and we look forward to showing label converters the next stage in the evolution of the Durst labels and packaging at Drupa later this year.

This article was first published in the 2024 February edition of ProPack.pro magazine. Read the original article here

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@propack.pro

Sign up to the ProPack newsletter