Koenig & Bauer and Durst have accelerated the development of the VariJet 106 for digital production in folding carton markets with two beta sites confirmed and the first commercial customer starting production in a few weeks.

The VariJet 106 is the first joint development between Durst and Koenig & Bauer.

The first beta site of the VariJet 106 B1 single-pass digital press has started printing in May, and the second test customer will run the machine in a few weeks. Both sites are in Central Europe.

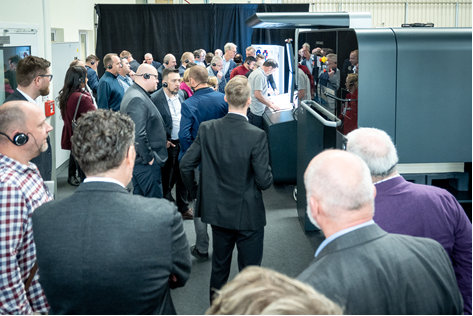

The announcements were made at Koenig & Bauer Durst VariJet 106’s Open House at the Sheetfed Division of Koenig & Bauer in Germany on April 26-27.

Koenig & Bauer Durst managing director Robert Stabler said, “Built on market-proven technology, the VariJet 106 installations represent huge statements to the market – and we are really pleased with the substantial progress that has been made.

“Production is being ramped up, and new machines will become available in the second half of 2023 on the back of the relatively high demand we are witnessing.”

According to Stabler, these presses are tailored to individual requirements enabling customers to optimise their production and reduce costs while offering new added-value business models.

The VariJet 106 press combines digital inkjet and classic offset printing. It is based on water-based inkjet processes to provide print quality. The platform is based on Koenig & Bauer’s high-performance Rapida 106 platform and Durst printhead electronics, inkjet expertise and Durst workflow and RIP technology. This includes Durst Analytics, Smartshop and Workflow.

“It brings together the strengths of digital inkjet and classic offset printing,” Stabler said.

Koenig & Bauer Durst’s VariJet 106 can produce up to 5,500 sheets per hour and uses de-inkable inks to increase packaging sustainability and comply with all the main food security standards.