Durst had its Tau RSCi and Tau 330 RSC E machines running at the recent Labelexpo Americas tradeshow to show attendees the potential of the presses

Durst created its Tau RSC platform to offer the benchmark in productivity and flexibility. And to improve reliability, simplicity, speed and cost effectiveness so label converters can better meet changing market needs with digital technology, the company has been constantly updating the fleet.

Durst took to the recent Labelexpo Americas tradeshow in Chicago to showcase this highly successful and globally placed Tau RSC range, offering attendees a unique experience by having on display the Durst Ecosystem of printers and software, and providing visitors access to experienced industry experts.

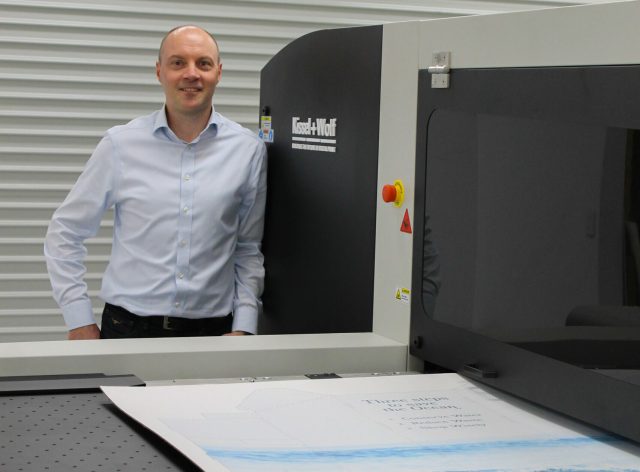

Durst not only had on display the Durst Tau RSCi and its Durst Tau 330 RSC E machines but also had the presses running to show attendees the potential of the units.

“As the label market shows an unstoppable level of growth, Durst is committed to match that with innovation and investment. As such, Durst Oceania is pushing heavily into the labels and packaging sectors,” Durst Oceania managing director Matt Ashman said.

“We’ve significantly grown our label press installation base this year, and we’re going into more high-speed packaging production. Oceania is a positive growth region, and Australia is a very vibrant, innovative and young market when it comes to labels and packaging.

“There are plenty of great businesses here and we just want to be a part of that upward trajectory.”

According to Durst, Tau single pass printing systems now have a market share of around 40 per cent of the UV inkjet market segment, with an installation base of more than 320 printing presses worldwide.

A machine for many benefits

Designed for an industrial level of productivity, the Durst Tau RSCi offers the highest quality, in the most economical way. Available in printing widths of 330mm, 420mm or 510mm, the printer is designed to take over mid- to long-run jobs and is also able to produce short-run jobs.

The user-friendly design including jumbo winders and roll lifts allows fast roll changes and good accessibility to print heads, UV-lamps and transport rollers. The integrated large inspection table provides space for visual inspection. The Tau RSCi is equipped by default with a chill roller to guarantee maximum material and application flexibility.

“At the start of 2021, we finalised the beta of the RSCi – the industrial platform leveraging all benefits of the standard RSC but with print widths up to 510mm and printing speeds up to 100m/min, and optional inline flexo stations prior and after the printing unit,” Ashman said.

“The introduction of the Tau RSCi has generated a large amount of interest in the marketplace since it was launched in September 2020.”

Durst labels product manager Martin Leitner was at the Labelexpo Americas tradeshow, explaining to attendees about the capabilities of the company’s RSCi technology.

“Labelexpo Americas was a great event, with lots of people showing interest in our products. The RSCi printer that we had on the show floor was a 330mm-wide, sevencolour model – white, violet, orange and CMYK,” he said.

“The press shown had a print engine with the standard high-performance RSC technology – so we print at 1200 by 1200 dpi, two picolitres and up to 100m/min.

“We had our standard equipment with unwinder and Corona pre-treatment stations as well as a flexo station on the machine as we showed some new applications using pressure-sensitive labels such as in-mold labels (IML) and shrink sleeves.

“Something new that we have launched on this press is a feature specially designed for customers that are printing heavily on transparent materials, such as personal care and beauty products. This feature allows customers to use two white stations, which we call double white, which increases white productivity.

“This allows the machine to print white and all the other colours at 80m/min. In addition, our high opacity white mode has been increased from 40m/min to 52m/ min for better productivity levels. That’s what our customers need.

“The printer almost does everything by itself including the maintenance and cleaning, so there is no need for the operator to constantly clean things like the print heads. Our machines are of solid construction, and ready for production.

“The configuration that we had on the show floor had another flexo station after the print station for shrink sleeves. IML and shrink sleeves generate a lot of interest, with IML not traditionally done on digital machines. But with the RSCi, this is now possible and done with quality and high productivity levels.

“This press, in this configuration, is made for heavy work. That matches production speeds of our customers as evidenced by the many global customers that have installed the machine.”

Businesses such as LabelPrint OÜ in Estonia and All4Labels Global Packaging Group in Germany have experienced the benefits of the Tau RSCi range.

All4Labels installed a Tau 510 RSCi at its Gebesee plant in mid-2020 and tested the press under real production conditions for a dedicated range of label and package printing applications.

Thanks to the positive performance of the beta machine, another machine has been installed in the same press room to further increase production capacity needs in the premises, followed by multiple installations in other All4Label plants across Europe.

At LabelPrint OÜ, the company has been using the Tau RSCi to actively develop digital print services to its client base.

“Some of our customers have installed three or four of these Durst Tau RSCi machines as these presses are workhorses and can keep up with heavy workloads. The technology, quality, and productivity of inkjet is now available with this machine,” Leitner added.

“In addition, Durst has invested and is continuing its investment in the knowledge of applications using the Tau RSCi as customers not only need a good machine but also the support from us to help them use the press for a range of applications.”

A future-proof press

In addition, Durst showcased its standalone UV inkjet label press, the Durst Tau 330 RSC E at Labelexpo Americas. Designed to evolve with a business, the machine is fully upgradeable to grow with customers.

Similar in construction to the RSC E, the adaptation of the press includes the new Durst corporate design, with all well-known features installed. These include the infeed section which has sensors, a double-sided web cleaner, a corona treatment feature and an insetter for reinsertion and double-sided printing.

Durst at Labelexpo Americas

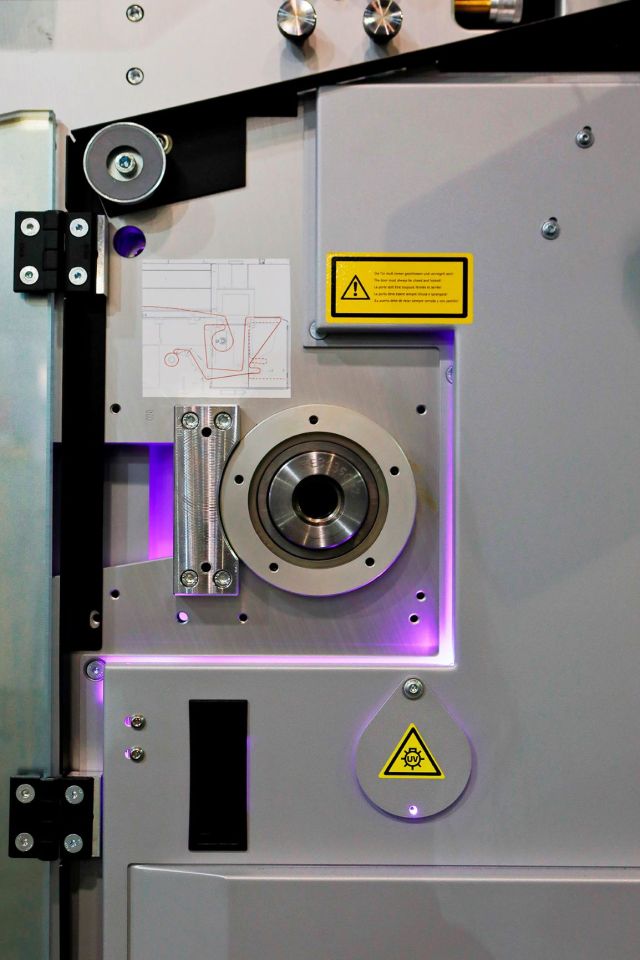

The outfeed section is where the final curing takes place with two UV lamps around a chill roller and an operator inspection table with a camera for automatic nozzle compensation.

The printing unit centrepiece holds eight colours, including white and optional green, violet and orange, cyan, magenta, yellow and black. New added options such as the high-speed white function allows operators to print with all colours and white.

All colours have eight printheads which can print 80m/min, guaranteeing that future increased production capacity requirements are covered, at 1200 dpi resolution, offering superior print quality at all levels of investment.

“Durst had a second booth at Labelexpo Americas, showcasing the Durst Tau 330 RSC E. Durst has a complete range of presses in our portfolio, all with the same printing quality but only variations in the productivity,” Leitner said.

“The Durst Tau 330 RSC E is ideal for customers that want to start with inkjet or want to increase their digital capacity. For customers that print one to 1.5 shifts, and up to 50,000 or 60,000 square metres a month, this model is really their ideal press.

“The press that we had on the show floor was in a five-colour configuration – CMYK plus white, as well as several new features included. This press has been installed in more than 200 premises around the world and customers love it. They make labels with it, so what we wanted to do was improve on automation and provide them with a stable production press.

“So, the main new feature for this model is a Durst-developed camera system for density alignment of the press – we want to ensure that all the prints have the same colour on them. We also use the camera system for offset and print head alignment.

“Humans have different perceptions of quality so with this camera system, that quality is now measurable. The camera system pairs with Durst’s software which ‘tells’ the technician when he installs the press how to reach the ideal result.

“Durst has automated and continues to automate our presses to offer very competitive solutions.”

All you need is RSC

All Durst printers come fully equipped with Durst Workflow and Durst Analytics software, and optional Durst Smart Shop software, enabling web-to-print solutions.

“Our software also includes the LinkSafe feature, which helps reduce ink costs on average of about 12 per cent. This makes it much more competitive, and our customers that have used this feature have provided us with feedback that it works much better than they expected.

“This feedback is great for us as it tells us that our customers are successful – and that’s our goal.”

Visitors to the Durst booth at Labelexpo Americas were also able to view the vast functionally of the company’s software and received demos on special features such as precise ink cost analysis, exact colour rendition, and high-speed ripping.

The Tau RSC platform printers can print on a large variety of substrates and the software solutions offered by Durst Workflow Label ensure an integrated workflow combined with secure handling of sensitive job data. Ease of use, intuitive and automated, the Durst Label Software tools are also included to help businesses organise their production workflow to be more efficient and cost effective.

Applications for the Tau RSC range include, but are not limited to, the beauty and care, food and beverages, and chemicals industries.

In beauty and care, the Tau RSC provides the highest opacity white, vivid colours and a screen-like feeling of the label prints. Patternware adds additional value, to further enhance the appearance on the shelf.

In food and beverage, abrasion resistance and temperature stability are key for these applications. Furthermore, it also enables labels to be produced in a vivid and strong manner, in compliance with general industry regulations and standards.

In chemicals, the Tau RSC UV ink provides excellent durability, resistance, and light fastness. Resistance has been proven, for example, with tests against gasoline or methylated spirit. Many Durst Tau RSC clients produce millions of labels for chemical applications such as oil bottles, fertilisers, detergents, hand sanitisers and many other industries.

Durst USA labels and packaging director Steve Lynn said, “We were excited to be back on the Labelexpo show floor, showing the strengths of our RSC portfolio with 1200 dpi inkjet technology. Durst equipment has a reputation for reliability, quality and speed – LabelExpo Americas 2022 allowed us to show those strengths to the entire label community. It was a great show, and Durst was proud to be there.

“It was certainly an exhilarating event for people to see how and why Durst keeps them printing.”