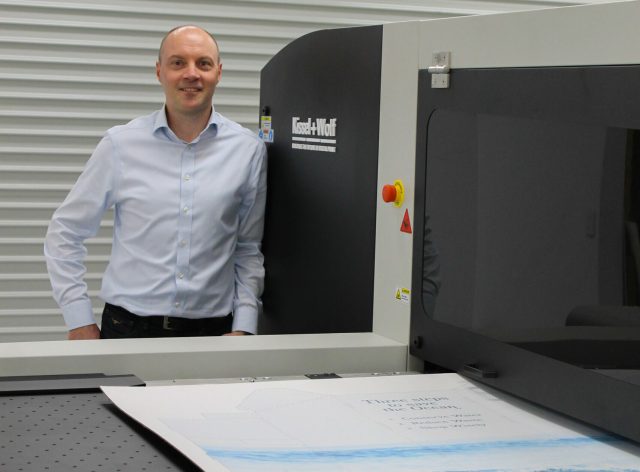

(l-r) Charters Paper executive chairman Robert Iervasi and CEO Michael Sfetkidis inspect samples

Charters Paper invests in a Garant Maschinen Matador NXB with four-colour LINAFLEX NL inline printing to strengthen its paper packaging capabilities.

Charters Paper, an Australian family-owned and operated business established in 1991, has made one of its biggest investments to date – the purchase and install of a Garant Maschinen Matador NXB machine with four-colour LINAFLEX NL inline printing, boosting its recently-developed packaging arm.

The arrival of the machine in January 2024 has already enhanced the company’s packaging offerings, providing its customers with better quality products and more sustainable options.

Charters Paper specialises in the manufacture, storage, and distribution of plain and pre-printed thermal receipt paper rolls, ticketing, and associated products for the retail, banking, hospitality, gaming, entertainment, medical, and transport industries. It has an exclusive distribution agreement with the world’s largest supplier, Graphic Controls, for its thermal TITO Tickets and is licensee across Asia Pacific for StickyPOS linerless labels.

Based in Melbourne and employing 25 staff, Charters Paper’s headquarters houses its manufacturing, sales, customer support, logistics, and finance teams.

Even though the company retains market leadership in this space, it made the decision to diversify and branch out into the food packaging space to tap into new areas of play.

In response to the surging demand for eco-friendly packaging, Charters Paper invested in its paper packaging capabilities in 2022, when it expanded into the production of flat paper bags and grease-proof sheets, resulting in its exclusive agreements with major suppliers for innovative paper-based packaging products.

“For over 30 years, Charters Paper has been a trusted provider of thermal paper solutions to Australia’s top companies,” Charters Paper CEO Michael Sfetkidis said.

“Expanding our expertise into sustainable paper packaging was a natural progression for the business as we have been in the paper and printing industry for a long time, allowing us to better serve our customers and the environment.

“Our focus was to diversify the business into food packaging, specifically the production of paper-based packaging products. Most recently, we also signed a distribution agreement for 100 per cent paper bubble wrap.”

A leg up into food packaging

According to Sfetkidis, when Charters Paper first acquired equipment for food packaging, it procured the work of some well-known bakery brands, providing a strong foundation for its entry into the field.

“At the time, we were able to ‘piggyback’ on this deal for all other paper bag jobs. The bans on single-use plastic bags across Australia further catapulted our strategy into paper-based packaging products,” he said.

When the business began in the food packaging space, it was using second-hand equipment. However, the company soon found it needed to improve its automation to meet growing demands.

“The strategy was always to start off with second-hand equipment, build the business, and then get the best available machinery for production,” Sfetkidis said.

“We saw a big demand very quickly since our first entry into the food packaging area. The volume of work multiplied fast. There was a need locally for fast turnaround ink on paper and ink on bags. Since we have a relatively small team, the need for us to operate as efficiently as possible arose.”

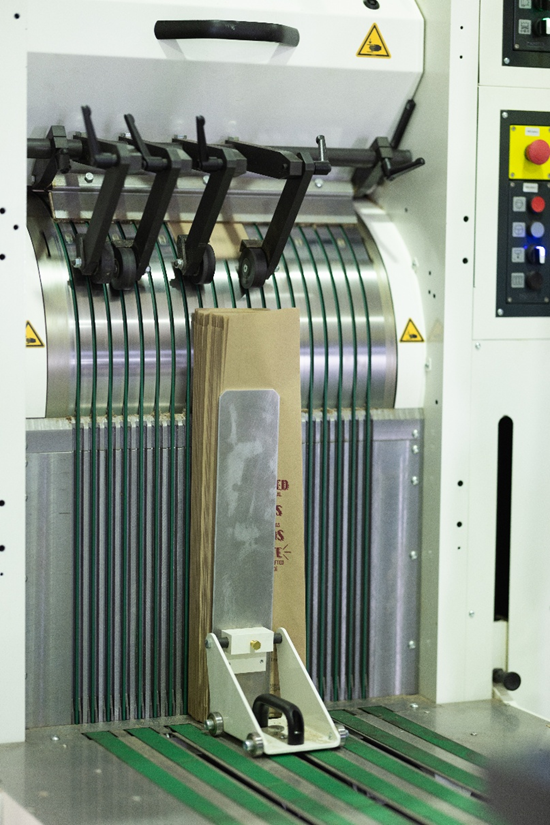

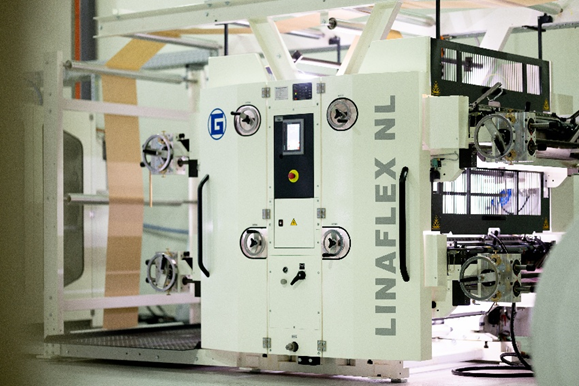

As a result, it purchased a state-of-the-art Matador NXB flat and satchel paper bag machine, configured with four-colour LINAFLEX NL inline printing, from Garant Maschinen, a German leader in paper-converting technology.

Charters Paper purchased the equipment direct from Garant Maschinen, which is a member of the Windmöller & Hölscher (W&H) Group. The local W&H agents helped Charters Paper through the purchase and install process.

“We did some research when we attended Interpack 2023. We saw a handful of machines at the tradeshow, but the Matador NXB stood out for us and was our pick of the bunch. From there, we worked very closely with W&H Australia and its headquarters in Germany to get the machine into our premises,” Sfetkidis said.

A highly efficient machine

The Garant Maschinen Matador NXB boasts impressive capabilities. It can produce a wide range of flat and side gusset paper bags at speeds of up to 1,200 bags per minute. It runs a standard size two square bag in a dual-web production method.

Additionally, the machine offers four-colour printing, creating a one-stop-shop for efficient, customised paper bag manufacturing.

Sfetkidis said this investment enhanced the company’s flexibility, enabling it to offer faster turnaround times, and reduced setup and production times.

“This investment empowers us to deliver exceptional quality paper bags with guaranteed supply and faster lead times. We’ve got much more capacity, and it enables us to do longer runs in a shorter time,” Sfetkidis said.

“This allows for more flexibility within the business, especially for any urgent orders or quick changeovers. It gives us a wide range of bag sizes that we can manufacture, on a standard machine.

“Several existing clients have already benefited from the Matador’s capabilities, receiving high-quality, branded paper bags. They’ve provided us with feedback, saying they’re impressed by the fast turnaround times, the quality of the bag, and the print that’s being produced.”

The four-colour configuration was chosen as Charters Paper has always been a believer of inline printing. The company also owns two other machines that it uses to print inline for thermal rolls.

“With the four-colour option, we get several accommodations. A lot of work is two-colour, but we can now set up the other two units while it’s running for quicker changeovers. It also gives us an advantage over our competitors that are probably limited to one or two colours,” Sfetkidis said.

“We can also deliver solutions to the market quicker than people that are buying in from China, where they’ve got to wait for eight weeks minimum.”

One of the standout features of the Matador NXB for Sfetkidis is the flexo chamber blade system, which allows Charters Paper to better control the ink laid down, resulting in a much clearer image.

“This machine has given us more flexibility than we have ever had before. Because of that, our go-to-market offering is unique and unlike many others. It has set us apart from the pack,” Sfetkidis said.

Putting sustainability at the forefront

The acquisition of the Matador NXB aligns with Charters Paper’s ongoing commitment to develop its sustainable packaging solutions and caters to the growing demand for eco-conscious alternatives.

Charters Paper’s sustainability strategy includes a waste management program where it works with suppliers to remove plastic out of its supply chain. It has been FSC Certified since May 2011, has held Sustainable Green Print L1/303670 certification since 2012, and is a Supplier Ethical Data Exchange (Sedex), and an Australian Packaging Covenant (APCO) member.

“The majority of our stock is FSC Certified. Our grease-proof papers and packaging papers are PFAS free. And with our thermal rolls, we are the only converter in Australia that manufactures coreless rolls – we only use coreless or cardboard cores, which support our customers in meeting their sustainability targets as there is less wastage and it gives us a competitive edge,” Sfetkidis said. “The Matador NXB supports our sustainability strategy in that it promotes the use of paper and the move from single-use plastic bags to paper bags. The future for us is to move to Hazard Analysis Critical Control Point (HACCP) certified and we’ll continue to invest in equipment for the production of fibre-based packaging or paper-based packaging.”

What’s next?

Charters Paper will continue its investment into Australian manufacturing, especially paper-based food packaging products. It will also continue to innovate through its global network of contacts and suppliers.

“We’re always looking forward to innovation. That has been on the Charters Paper agenda for years. Despite being in a commodity-based business, we’ve always looked to add some specialty products, which we will continue to do in the coming years,” Sfetkidis said.

“We’re looking into products like self-opening satchel (SOS) paper bags with inline printing as there’s a market for that. There are also opportunities for digital printing for paper-based food wraps, which can be used for labels as well.

“In addition to that, our plans involve increasing our range of products – either through distribution deals with global companies or manufacturing them locally. We want to be first to market and offer the market flexibility for printed products, with fast turnarounds.”