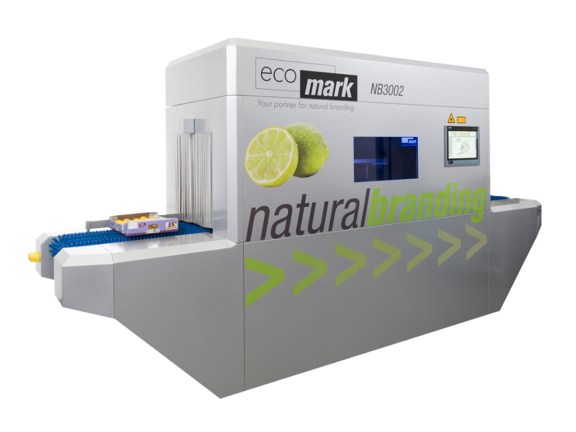

Result Group has partnered with EcoMark and Macsa, global companies in the coding and marking space, to bring Natural Branding to the Australian market. This technology uses EcoMark laser technology to produce a wide range of codes on fruits or vegetables without needing consumables.

The new EcoMark Natural Branding provides a non-contact and safe labelling technique that creates an image on the peel using a high-resolution laser to remove the colour from the fruit or vegetable’s outer layer of skin.

EcoMark Natural Branding is a new, sustainable, and cost-effective technology which can potentially eliminate the need for fruit labels and the silicon liner that goes with them.

Utilising a laser for the marking, the system ensures branding, SKU-level identification, traceability and authenticity while producing no long-term damage and barely detectable heat on fruits and vegetables. The system simply depigments the uppermost cell layer of the fruit’s skin and removes the outermost layer of skin, preserving the fruit’s integrity.

Natural branding can improve traceability and assist in reducing label use for environmental and economic reasons. In the process, no inks or chemical additives, packaging materials, colours, or stickers are used.

It can be used virtually on any fruit or vegetable with a robust skin, including apples, avocado, banana, kiwi, lemon, cucumber, ginger, garlic, onion, carrots and even cauliflower, to name a few.

Due to its adaptability and ease of production line integration, it is becoming increasingly popular for conventional goods such as bread, biscuits, chocolate, and other confectionery products.

The EcoMark machine can produce 2D codes Datamatrix and QR, logos, certification marks, shapes, numbers and text. The use of the GS1 digital link standard enables coding a wide range of information, including the source of the product, use by date and origin information. It is still acceptable for point-of-sale scanning and consumer engagement via any smartphone camera or app.

The Eco Mark Natural Branding system features a product handling system designed around the product or products being marked, a 3D camera for vision and mapping, locating the exact place to mark the product, the laser coder and upgradeable software that control and drives the entire system.

The machine is available in two models: Light and Professional, with both models featuring a conveyor belt, allowing objects to be marked “on the fly,” that is, without stopping. The products can be placed individually, in finished packs or boxes, or even on the conveyor belt chaotically. The integrated camera detects the position and orientation of the objects to be laser marked-cut automatically. There is no need for operator intervention.

“In over 35 years of coding and marking and spending a good part of those years exploring the world for innovation, I have seen nothing like this system, nor the potential for expansion in other markets outside of fresh produce. Simply put, this can and will re-invent coding and marking in the coming years,” Result Group general manager Michael Dossor said.

As a GS1 Australia Strategic Alliance Partner, Result Group said it sees enormous potential in leveraging innovative technology by collaborating on future projects with GS1 and the entire industry. Result Group is already working with several industry bodies providing the technology for growers.

The EcoMark Natural Branding machine has been installed in the Result Group’s demo room. Contact the Result Group to schedule a demonstration session to learn more about the technology.