New research conducted by Aquapak Polymers has found that ‘recycle ready’ adhesives and fully soluble barriers can replace plastics in fibre-based packaging, making it fully recyclable in high volume recycling mills.

The new technology is non-toxic, marine safe, dissolve and subsequently biodegrades, but still provides the much-needed functionality required for food, drink and household product packaging.

The study was commissioned as the move to replace conventional, hard to recycle and single use plastics has resulted in a wide variety of fibre-based packaging formats combined with alternative functional barriers being introduced into the recovered paper recycling streams.

However, the materials currently being used to give paper the packaging functionality required for products such as food, drink and household goods, are not easily recyclable and mean that the paperboard is rejected because paper mills cannot process the paper and plastic combinations. Instead, they are incinerated or go to landfill.

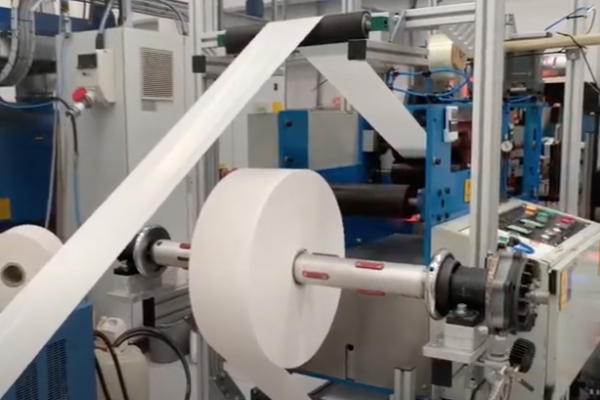

The research focused on Hydropol, a commercially available fully soluble, biodigestible barrier polymer, which can be adhesive or extrusion coated onto paper and brings a number of benefits to fibre-based packaging, including oil and grease resistance together with a high gas barrier.

Hydropol has also been shown to increase some paper strength properties (tear, burst, puncture and tensile strength), allowing coated or laminated papers to be heat-sealed for ‘form, fill and seal’ fibre packaging applications.

Hydropol is designed to solublise at the typical repulping temperatures and durations used by high volume recycling mills allowing fibre to be dispersed to make new paper.

The report also identifies that independent tests reveal that once solubilised, even when Hydropol coated paper forms 20 per cent of the fibre furnish, it is biodegraded in the mills’ anaerobic digestion and aerobic activated sludge treatments as part of its intended use. Hydropol is non-toxic and biodegradable in the marine environment should it be littered, forming no micro-plastics in the environment.

The results of the study confirm that most laminating adhesives can disrupt the recycling loop; they can ‘lock-in’ valuable fibre and, in some cases, result in more than a quarter of fibre associated with some adhesive laminated packs being lost from the paper recycling process.

It also suggests that using non-repulpable laminating adhesives could consign paper and board packaging to the ’Don’t Recycle’ category – an undesirable outcome for producers, brands and retailers who are turning to paper fibre-based packaging as the ‘green’ alternative to plastic.

Aquapak chief technical officer John Williams and co-author of the study said, “Maximising fibre recovery rates is the goal of a circular economy approach and the designing of recyclability in packaging should focus on the practicalities of fibre recovery in the mill and at eliminating all elements contained in packaging such as adhesives and conventional plastics, which impact on negatively on this process.

“The study illustrates the importance of designing-in and testing fibre-based packaging to confirm recyclability under the repulping conditions used by high volume recycling mills. In addition, the work demonstrates that ‘recycle-ready’ packaging adhesives and fully soluble, bio-digestible barrier systems are available to designers to manufacture recyclable fibre-based packaging.”