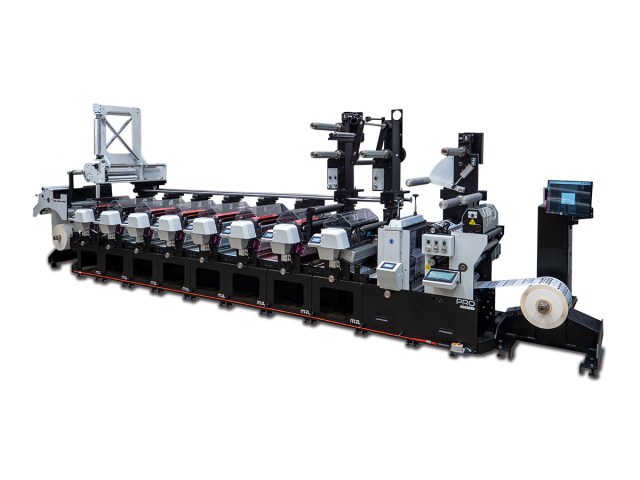

Mark Andy has returned to premiere its new fully servo-driven PRO Series flexo press and showcased modern technologies developed to help converters succeed in the highly competitive label and packaging market.

Mark Andy is marketing the new PRO Series machine as the first fully servo-driven CE certified flexo press at an affordable price point, providing an efficient and effective workflow, low machine operating costs and offering an upgradable design that allows converters to expand their flexo capabilities or easily transition into digital with a toner-based engine.

PRO Series shares the award-winning Performance Series printhead design, resulting in time and material savings while maximising profits and productivity. It is compatible with sMArt link for production monitoring and analytics.

PRO Series is also the flexo platform for Digital PRO Max, a toner-based digital press with a low cost to print and exceptional white.

Rounding out the Mark Andy press offering is its top-of-the-range hybrid press, the Digital Series HD, featuring a unique combination of Mark Andy’s flexo print stations and a UV Ink Jet engine.

Mark Andy’s premier hybrid press, Digital Series HD (DSHD), equipped with the proprietary digital and flexo print technologies, is printing on the stand at speeds up to 73 metres per minute.

It combines high-resolution digital print and best-in-class production capability into a single pass workflow. The Digital Series HD is equipped with value added print features and an automatic turret rewinder, demonstrating Mark Andy’s ability to provide end of line automation solutions.

Its European debut also makes the Digital PRO Max, a toner-based hybrid press built on the new PRO Series platform. It is a result of Mark Andy’s long experience in digital technology combined with significant feedback from users of previous Digital Pro models. The Digital PRO Max is faster, has lower cost-to-print, includes toner white, and can be available in configurations from roll to roll up to full hybrid. The combination of this digital engine on the future-proof PRO Series platform yields higher speeds, more productivity and increased profitability.

Premiering at Labelexpo is ProWorx Label Suite, an exclusive imposition tool. This new software streamlines and automates label production setup, including inline printing and embellishment processes.

ProWorx Label Suite is an Adobe Creative Cloud extension tailored to Mark Andy’s hybrid presses. It provides job defining and imposition for printing and post-processing, including die-cutting, and allows for more efficient and sustainable label production.

For end of press automation, Mark Andy has partnered with Lemu Group. The MA-GTU automatic turret is featured at the end of the Digital Series HD press. It eliminates the need for manual transfer of finished rolls to an offline finisher, minimising additional work processes and operator oversight thus improving productivity and profitability for the converter. The collaboration offers label converters the MA-GTU automatic turret plus additional automation with ‘unwind to palletiser’ printing and converting solutions.

Mark Andy senior vice president of marketing and business development Greg Palm said, “We are excited to be returning to Brussels and Label Expo Europe. Over the past four years the market has changed, and the industry has advanced in many ways. We are looking forward to showing how Mark Andy has embraced those changes with our robust product offering that meets the needs of today’s label and packaging converters.”

Mark Andy Print Products (MAPP), the OEM parts and consumables division of Mark Andy, is also in Brussels. MAPP provides a growing and comprehensive portfolio of end-to-end solutions for label production including supplies, consumables for flexo, digital and offset printing.