Flint Group Narrow Web’s Evolution Deinking Primer has won the Environmental Sustainability Award at the Global Label Awards, announced on the show’s opening night, on 13 September.

The company won the award as the judging panel felt that the primer makes a major contribution to developing a circular lifecycle for label materials.

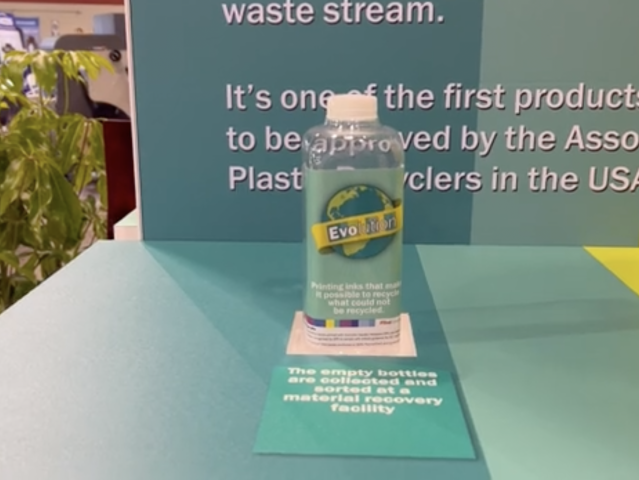

Flint Group Narrow Web demonstrated this technology at Labelexpo Americas, highlighting how its new Evolution Series coatings boost the recyclability of shrink sleeves and bottles made from crystallisable PET.

Both recommended by the Association of Plastic Recyclers in the USA, the coatings – a de-inking primer for shrink sleeves and an overprint varnish for PSL labels – prevent ink contamination during recycling.

This in turn keeps the PET clear in the waste stream, and therefore valuable for recycling into new packaging. The coatings use only one printing station and require no changes to the converter’s existing ink system or curing processes.

The Evolution Caustic Resistant Over Print Varnish is a clear coating that is applied to the pressure sensitive label after the colours are printed. The varnish protects the ink, stopping it from bleeding out in the caustic wash.

After the bottle and label are ground down, the pressure-sensitive label flakes cleanly separate from the package in the caustic ‘float-sink’ bath. The label material containing the protected ink floats to the top and can be skimmed off to an alternate waste system, leaving the uncontaminated PET flake in the recycling stream.

“The over print varnish has a recommendation from the Association of Plastic Recyclers – not just for use with the base material, but for the integral label system. This ensures we have a solid sustainability proposition for our customers,” Flint Group Packaging North America global key accounts technical director Dr. Paulo Vieira said.

The Evolution Deinking Primer for PET shrink sleeves is a primer that goes between the ink and the sleeve itself. When the package is recycled, the primer enables the ink to separate from the sleeve and wash away in the caustic bath. The ink and sleeve go their separate ways: the ink and the primer rise to the top of the caustic wash and are swiped off.

“This leaves behind the sleeve, which until now had to be taken to landfill, remains in the recycling stream with the bottle – and adds anywhere between 3 and 6 percent of the sleeve pack back into the recycling chain,” Dr. Vieira added.

Both coating products are Dual Cure UV flexo inks, curable under LED lamps as well as conventional mercury lamps.

“Evolution series coatings provide converters with a fast and smooth solution to improving the sustainability of their offering – as well as that of their brand owner customers,” Flint Group North America vice-president Julian Cass said.

“No additional printing stations are required: the converter can be offering a recyclable pack in the short time it takes to exchange one coating station on the press.”