Jet Technologies, has announced it is offering AFP-R reduced solvent flexographic plates from Asahi Photoproducts.

The AFP-R plate represents cutting-edge platemaking technology, with a 50 per cent reduction in platemaking time and a 30 per cent reduction in solvent usage.

The AFP-R plates have been proven to last twice as long on press compared to other solvent-wash plates, contributing to operational efficiency and environmental impact.

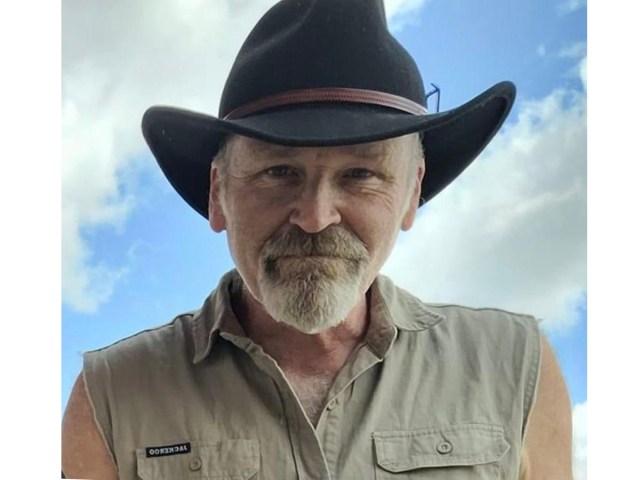

Director at Jet Technologies, Jack Malki highlighted the significant benefits of the AFP-R plates.

“The introduction of Asahi’s AFP-R plates is a game-changer for Australian and New Zealand printers. Not only do these plates ensure a dramatic reduction in platemaking time and solvent use, but they also support our client goals for sustainability without compromising on quality or productivity,” said Malki.

The AFP-R plate is designed for high-quality flexible packaging, label, and paper applications. It embodies Asahi Photoproducts’ commitment to sustainability and forms part of its Roadmap to Solvent ZERO initiative. It features reduced environmental impact while enhancing pre-press and press productivity.

Furthermore, the incorporation of Asahi’s CleanPrint technology means that clients can achieve better press efficiency. Plates last on average twice as long due to the reduced need for press stops for plate cleaning. This technology ensures that all remaining ink transfers to the printed substrate, further reducing makeready time and ink consumption and delivering exceptionally consistent quality.

“We expect to see some great outcomes for our customers in their platemaking and printing processes,” said Malki.

“This cutting-edge technology is expected to double the lifespan of plates by significantly reducing the need for press stops for cleaning. We anticipate that CleanPrint will ensure a more efficient transfer of all remaining ink to the printed substrate, which will not only reduce makeready time and ink consumption but also deliver exceptionally consistent quality across all our projects.”

Jet Technologies says its introduction of the AFP-R plates is set to bring new opportunities and efficiencies to the flexographic printing industry, reinforcing the company’s dedication to innovation and sustainability.