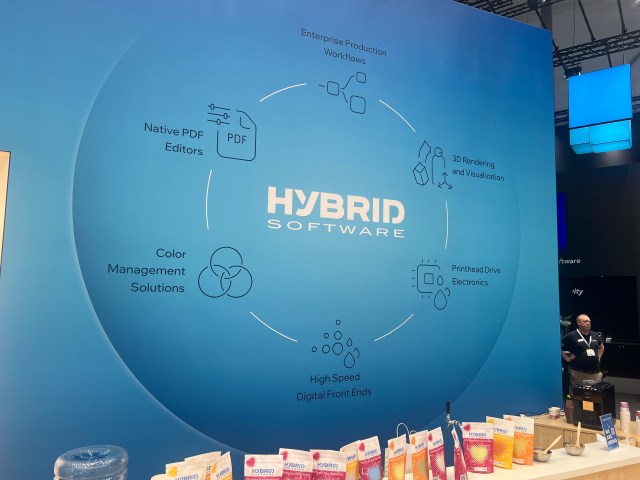

Artificial Intelligence (AI) was a hot topic at the recent ProPack Packaging Forum, with several speakers addressing the technology in their speeches. One of them was Hybrid Software product manager Pascal Wybo, who addressed the role of AI in revolutionising the packaging industry.

According to Wybo, from a technology point of view, AI is just a logic evolution of statistics and analytics. But, he said AI is actually AI when technology tries to simulate human intelligence and is descriptive, diagnostic, predictive, prescriptive and generative.

“It should be able to interpret tons of data today, in every label and packaging company. You should get business intelligence out of it. Artificial Intelligence can only be called Artificial Intelligence if it’s able to learn – your workflow automation that you have today, is not Artificial Intelligence,” he said.

“In addition, AI should be able to generate business improvements without a human being involved. AI is going to reshape the packaging industry. It will help companies improve efficiency, reduce costs, enhance quality, and create new opportunity.

“From design and pre-press automation to predictive maintenance, AI will be the catalyst for innovation and operational excellence at the production floor.”

Wybo said AI will help solve current challenges that converters may be currently facing, such as labour-intensive designs, staff working long hours, high material waste, inefficiency in print runs, downtime due to equipment failures, a lack of predictive maintenance, as well as rising demands for personalised labels and short run jobs.

“As a software technology provider, we see AI as the catalyst for development, end user excellence and innovation in software creation. AI can monitor your workflows, your software, and your hardware. Hybrid Software uses AI for internal product and solution problem solving. We want to guarantee you quality,” he said.

Wybo also spoke about an AI label and packaging project that Hybrid Software was involved in. The Johnnie WalkerDiageo Blue Label personalised bottles was a generative AI-powered experience that allows guests to co-design a personalised bottle of Johnnie Walker Blue Label.

The experience prompted visitors to answer three simple questions that influenced key themes in Scottish artist Scott Naismith’s work, ultimately impacting their bottle design. The simple prompts generated various colours, locations, artistic styles, and times of day, resulting in a unique bottle that was printed in a matter of minutes.

Wybo said projects such as this comes as consumers increasingly search for unique experiences and products that signal belonging, status, and personality. He said consumers are going beyond the most up-to-date cultural movements, seeking things that feel entirely original, with personalisation now a necessity.

“AI is going to be everywhere – even in your basic packaging processes, in pre-flight, colour management and your production floor. It is all about guaranteeing the quality of your label and package.

Wybo added that domains in packaging production that will benefit from AI include:

- Smart imposition and layout planning

- Cost and waste reduction

- Sustainability and compliance

As a first step, he suggested businesses adopt an AI directive involving five steps – identifying strategic challenges in the business, exploring the possibilities with AI solutions, selecting what you want AI to do, prioritising things that are important for your business, and validating your choices using the technology.

“AI is continuously evolving at lightning speed. If you want to be competitive in this industry, you should be using it,” he added.

The inaugural ProPack Packaging Forum would not be possible without the support from its sponsors:

Platinum Sponsor – Durst Oceania

Gold Sponsor – Cyber

Gold Sponsor – Miraclon

Bronze Sponsor – Hybrid Software

Bronze Sponsor – Kissel & Wolf

Bronze Sponsor – Koenig & Bauer