Winning the hearts of today’s consumers requires more than a great product. Increasingly, it’s also about the packaging. Every day, hundreds of thousands of products compete for attention at stores or are delivered to homes. The packaging creates the first impression and the first experience – of the product, the brand and the values it stands for.

The corrugated packaging market too, is growing fast. According to Smithers, over 160.5 million tonnes of corrugated packaging was produced in 2020, with predictions for corrugated packaging consumption to grow an average of 3.8 per cent to four per cent by 2025.

In this new market reality, brands need a new strategy. Facing high demand, they need to deliver products in a flash to retail outlets and online customers, and provide exceptional unboxing experiences, all with minimal carbon footprint.

HP says digital printing of corrugated packaging can help with all three – fast delivery, unboxing and sustainability. By allowing a flexible supply chain and enabling high-impact graphics and personalised packaging, digital printing on corrugated enables fast delivery and great unboxing. It can also significantly improve packaging sustainability.

HP attributed recent reports that show the shift from plastic to paper-based packaging is supported by consumer beliefs and action. In a 2020 survey for the Paper and Packaging Board, 33 per cent of consumers said they avoid using plastics if they can.

Another survey, by McKinsey, found that almost 75 per cent of consumers are now willing to pay more for sustainable packaging.

As such, HP finds that digital printing can help with efforts to make packaging plastic-free. Fefco-published research showed 21 per cent of plastic packaging for producing e-commerce packaging and other applications can be easily replaced by corrugated cardboard.

HP said its commitment to making a sustainable impact and positive, lasting change for the planet, dovetails perfectly with the heightened focus on sustainability.

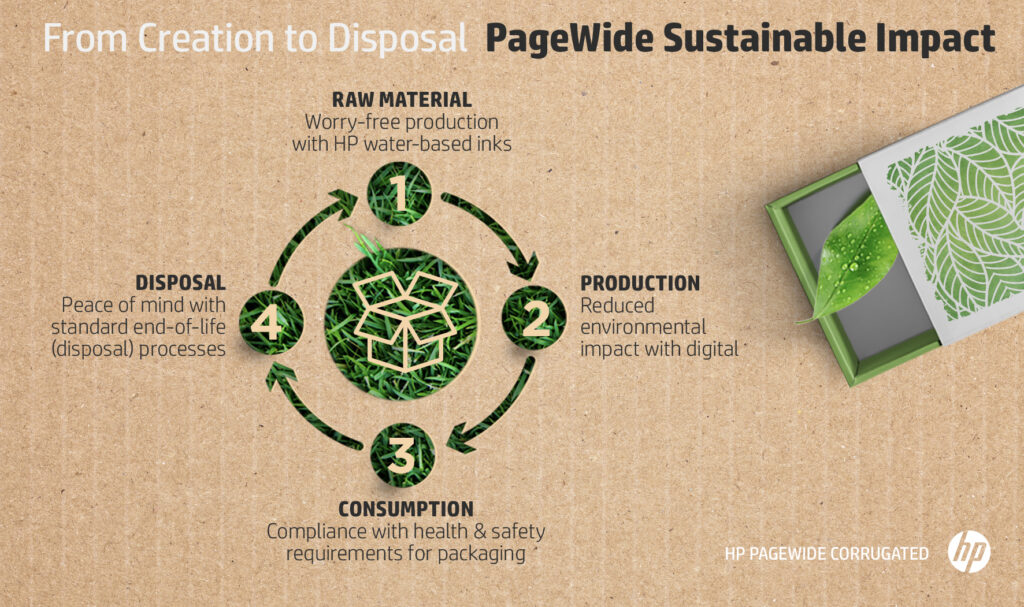

HP views the life cycle of a sustainable package through four stages: from packaging raw materials, through printing and conversion, to consumption of the packaged products and lastly, to the packaging disposal processes.

HP PageWide technology supports sustainability goals with HP PageWide true water-based inks that contain no hazardous air pollutants, supporting a safe and comfortable work environment. They are designed to meet worldwide regulatory requirements, such as UL ECOLOGO, USDA FDA, Swiss Ordinance and Nestlé guidelines, and to address a broad range of health and environmental considerations.

Digitally printed packaging allows print-on-demand in small quantities, reducing obsolescence, waste and warehousing. It also eliminates the need for harsh chemicals for cliché plate creation – another way to help the environment.

HP’s printing process itself is designed with sustainability in mind, with environmental benefits such as an automatic clean up procedure for the printheads, reducing the water used in press cleanup.

Brands are increasingly demanding their boxes meet sustainability standards for end-of-life processes. Boxes printed with HP PageWide inks can be recycled in standard processes and composted as they are certified to PTS for recyclability and Din Certco for compostability.

Converters who have invested in an HP PageWide corrugated press are already seeing sustainability benefits.

Victoria’s Italiya Graphics, which purchased the HP PageWide C500 Corrugated Press to expand its corrugated packaging and digital printing offering, is one such company.

“Our clients have been asking for more environmentally friendly processes for some time now and we needed to answer that call and leapfrog the traditional suppliers,” Italiya Graphics general manager Paras Italiya said.

“We love disrupting the market. Being a water-based, single-pass press, the C500 is the perfect press to ensure that our clients’ work is 100 per cent recyclable and compostable, while meeting and exceeding their quality requirements,” Italia Graphics managing director Vimal Italiya added.

In Seattle, US, Eighth Generation is using sustainable packaging to help tell its core brand values story.

The company, owned by the Snoqualmie Indian Tribe, works to spotlight Native artists by producing Native-designed products. To launch its limited-edition Gold Label Throw Blankets, Eighth Generation worked with custom box maker Fantastapack sustainable, custom boxes that match the blankets’ quality and beauty and the company’s brand values. It also wanted the flexibility to start with a small order and add more later.

“Digital print allows you to print what you want, when you want. This helps reduce overruns and obsolescence, which reduces physical waste. No machine setup or print plates reduces labor and material waste. And the HP PageWide C500’s true water-based inks, some of the safest in the market, reduce environmental impact on the whole planet,” Fantastapack vice-president of e-Commerce solutions Justin Stacey said.