Established in Sydney, Australia in 1983, Australis Engineering is a multifaceted provider of engineering design, materials handling equipment and industrial automation plus servicing and maintenance. It excels at designing and manufacturing innovative, fully tailored materials handling equipment.

According to Anthony Gustafson, engineering director, Australis Engineering, the company is guided by the ethic of smart thinking in motion and is all about simplifying complex problems and finding innovative engineering solutions that solve inherently difficult materials handling challenges.

He explains, “Smart thinking is delivered by our in-house engineering and trade experts meaning customers have direct access to the designers and technicians who are delivering your solution. Nothing is lost in translation and you do not have to outsource capabilities to multiple providers.

“Our customers choose Australis Engineering for our expertise in conveying, robotics, automation and materials handling and we have strong expertise in the beverage industry, including soft drinks, juice, water, milk, wine, spirits and brewing. We also understand the food industry, with expertise across raw meat, small goods, seafood, dairy and cheese, chocolate, confectionery, snack foods, biscuits, ice cream, fruit, vegetables, packaged foods, frozen food, patisserie, bakery and bread, grains, spices and oils.

“Following our visit to the 2018 ProPak Asia exhibition, Australis Engineering realised the potential to exhibit our own equipment in 2019.This year will mark the first-ever international trade show for our company. Following our scoping study in 2018, we were impressed with the scale and professionalism of ProPak Asia and the strong focus on the food industry,” he said.

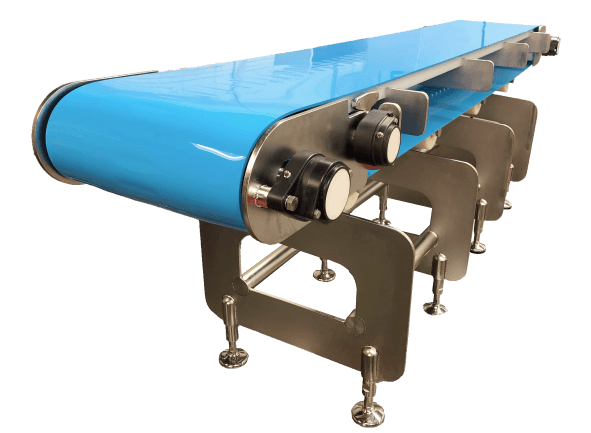

“Our decision to exhibit this year was also made easier by our new product development process which has resulted in the recent release of our Hygenius wash down conveyor for raw foods such as meat, poultry, seafood, dairy, fruit and vegetables.

“Hygenius will be a perfect introduction for Australis Engineering into the burgeoning Asian food machinery market and created the ideal entry point for us to exhibit at ProPak Asia in 2019,” Gustafson said.

Hygenius is a step-change in the way conveyors are designed and manufactured for the fresh food market. As members of the European Hygienic Engineering Design Group (EHEDG), Australis have taken the principles of certified, hygienic design and applied them to a food handling conveyor. Hygenius has been designed to minimise cracks and crevices where food or other product can accumulate and create bacterial growth which risks food safety. By removing material from the conveyor, the company says it has produced a conveyor which is very fast and easy to clean. In 2018, we were impressed with the scale and professionalism of ProPak Asia and the strong focus on the food industry,” he said. “Our decision to exhibit this year was also made easier by our new product development process which has resulted in the recent release of our Hygenius washdown conveyor for raw foods such as meat, poultry, seafood, dairy, fruit and vegetables. “Hygenius will be a perfect introduction for Australis Engineering into the burgeoning Asian food machinery market and created the ideal entry point for us to exhibit at ProPak Asia in 2019,” Gustafson said.

Hygenius is a step-change in the way conveyors are designed and manufactured for the fresh food market. As members of the European Hygienic Engineering Design Group (EHEDG), Australis have taken the principles of certified, hygienic design and applied them to a food handling conveyor. Hygenius has been designed to minimise cracks and crevices where food or other product can accumulate and create bacterial growth which risks food safety. By removing material from the conveyor, the company says it has produced a conveyor which is very fast and easy to clean

Have no long or dragging film tails “Our same principles of simple automation apply when we design our case erecting, tray erecting, case sealing and lidding machines. Our outstanding design features include an ergonomic blank infeed magazine that is power driven, not gravity fed. Cases are precisely formed and held in position while the flaps are folding, which makes a square case. We allow for easy and fast tape changing, and blank size changeover. You will find a wealth of resources on our stand in the Australian Pavilion at ProPak,” Fullerton said. Continued on page 6 2. Lantech S300 stretch wrapping machinery 2 impressive design outcomes of Hygenius is how quickly it can be disassembled and reassembled. Unlike other conveyors that can take up to 40 minutes to prepare for cleaning, the toolless design of Hygenius allows it to be disassembled and reassembled in less than two minutes and by people of any skill level.

“With the continued growth in the ASEAN middle class creating a demand for fresher and safer or more hygienic food production, Australis are ideally placed to bring our expertise to the ASEAN marketplace and build on our reputation of providing the best, engineered solution to manufacturing and warehousing challenges.

“Whilst we have exported our equipment to countries throughout the ASEAN region in the past, it has never been a singular focus and most projects were the result of Australian collaboration with a client wanting the same solution in the offshore facility. However, with our presence at ProPak Asia 2019, we are looking to make longterm inroads to the ASEAN market by introducing our brand and creating a local presence with an initial focus on the fresh food and beverage industries,” Gustafson said.