Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, and Esko, a global provider of integrated hardware and software solutions for the packaging, label and wide format sectors, have collaborated in the development of an innovative and automated flexo platemaking solution.

The collaboration aims to bring together key hardware and software technologies from both businesses to deliver a highly efficient and sustainable print form solution for the packaging sector.

“Today, flexographic companies are operating in a complex, fast turnaround industry, that often impacts their operational efficiency and profitability. For that reason, they need to simplify their processes while improving quality, consistency and profitability,” Asahi Photoproducts Europe technical marketing manager Dieter Niederstadt said.

“In doing so, they can create new business opportunities and positively transform their environmental impact.

“This breakthrough innovation will be different to other solutions on the market. It is not just an assembly of available plate making processes delivered inline, but rather a holistic approach to connecting technologies, up and downstream of the prepress process, using an intelligent automation hub as the backbone and heart of the solution.”

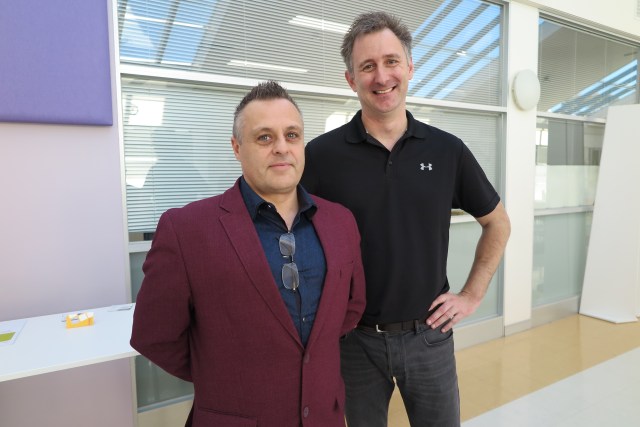

Esko flexo business director Pascal Thomas said the move is in line the company’s long dedication to improving the platemaking experience, in terms of quality, productivity and connectivity.

“Together with Asahi Photoproducts, we are taking the flexo platemaking process to a new level, enabling our customers to be even more competitive while also ensuring they can meet today’s demands for flexible and sustainable supply,” Thomas said.

“Our aim, by collaborating with Asahi, is to deliver a cleaner, more environmentally balanced operation, that simplifies the print form making process, improves safety and creates higher print quality consistency. The ultimate objective is to improve our customers’ overall business performance and profitability.”

Asahi products are distributed in A/NZ by Jet Technologies.

“The vision of replacing solvent flexo plates with a more environmentally-friendly alternative has always been out of reach due to quality deficiencies as well as productivity,” Jet Technologies director Jack Malki said.

“Combining the Esko Crystal XPS and Asahi AWP products sets a new benchmark for quality in the flexo market and with this new innovation, the productivity and automation is there to ensure that it can keep up with even the highest volume demands. It is truly an exciting achievement.”