XSYS has launched nyloprint WS PRO Digital, a water-washable, steel-based letterpress plate suitable for printing plastic tubes and cups, metal cans and aerosols, offering shorter processing times, durability and compatibility with all types of letterpress plate processing equipment.

Optimized for LED in-line exposure and brush washout, the new plate provides printing quality independent of the processing equipment.

It offers the high stability of the steel used with the nyloprint materials. It is less prone to kinks and irreversible bending and provides durability even in the longest print runs at high speed.

XSYS product manager and global key account manager for nyloprint Dr Christian Pietsch said, “Our customers are under constant pressure to deliver consistent print results quicker, cheaper, and more efficiently, so they need us to continue innovating in this field to give them a competitive edge.

“The new nyloprint WS PRO Digital represents a significant addition to our existing portfolio of letterpress printing plates, offering premium results in combination with LED exposure due to its excellent durability and high stability.”

Available in four thicknesses, the nyloprint WS PRO D letterpress plate offers better Overall Equipment Effectiveness (OEE) and is suitable for dry offset, rotary letterpress, imprinting units and special-purpose printing presses.

It exhibits higher sensitivity to UVA LED exposure than the market standard, meaning it can be processed faster on in-line UV units.

XSYS says that the new plate’s greater durability and long cleaning intervals further increase efficiencies on press. Combined with LED exposure, it delivers excellent print quality with especially superior highlights and the finest image details.

Due to dot sharpening, Customers can also experience lower dot gain in print.

Because the new formulation is less prone to plate deformation, other advantages include reduced plate waste and longer durability on the press, improving the production process’s sustainability.

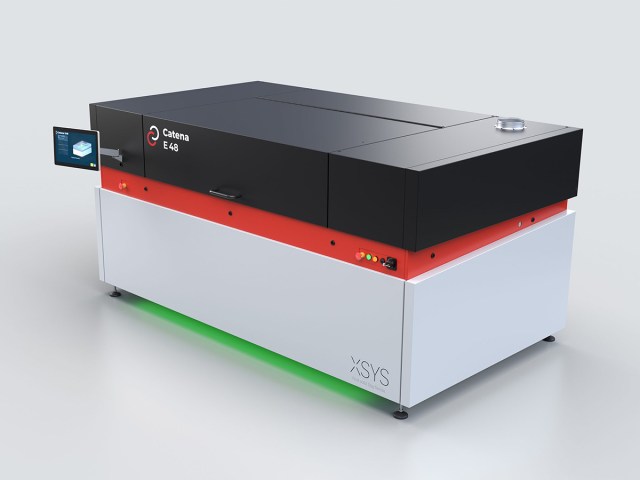

As well as being suitable for all types of processing equipment, including the XSYS nyloprint range, the new plate also works well with ThermoFlexX TFxX imagers fitted with a Hybrid drum (with vacuum channels and magnets).

Dr Pietsch added, “nyloprint WS PRO D presents a significant leap in productivity and efficiency, offering invaluable benefits to converters. This advancement empowers them to expedite product delivery without compromising on top-tier quality.

“Driven by its proven durability on the press, it not only reduces operational costs but also minimizes waste generation. This sustainability-conscious approach aligns seamlessly with the objectives of brand owners.

“With this introduction, XSYS continues its mission to provide brilliance for customers with the latest innovation in plates and platemaking equipment that allows them to succeed.”