This article first appeared in the October issue of ProPack.pro, authored by Greg Savage, the senior vice-president – Asia of Orora Group.

Glass has been used as a packaging material for centuries, dating back to ancient civilisations.

The benefits of glass are multiple and in many cases its properties are unique – it is transparent, inert, and impermeable to gases and liquids. It is also infinitely recyclable – it can be used again and again, without losing quality or integrity.

Even if it isn’t recycled or remanufactured, glass can be ground down into inert sand, minimising its environmental impact. These characteristics mean glass products are long-lasting, and their contents remain safe to consume.

Such traits are central to glass’ value proposition as a premium packaging option – wine, for example, can be cellared for decades while ensuring the product is still elegantly presented. This is particularly important now amid a trend toward ‘premiumisation’ – that is, the concept of “drinking better, less often”, which has been a consistent theme in recent years.

Despite this, in a modern world with an ever-increasing focus on sustainability, the environmental credentials of all forms of packaging are under scrutiny. Customers and consumers expect products to be made responsibly. Glass is no exception.

The reality is that the manufacture of glass is not without its unique challenges. It can be energy intensive to produce, while bottles can be both heavy and fragile, creating logistical and environmental challenges.

So how do packaging companies like Orora ensure glass remains the format of choice while also ensuring it is sustainable and environmentally friendly?

Orora has invested in a number of initiatives and technologies that are designed to ensure the ‘future-proofing’ of glass.

Decarbonisation – The art of low carbon manufacturing and bottle light-weighting

One of the key challenges facing the packaging industry is reducing its carbon footprint. A central part of that is adopting cutting-edge, lower energy intensity furnace technologies at our glass manufacturing facility at Gawler in South Australia.

With several furnaces operating around the clock, the energy requirements are substantial. However, from next year we expect to cut site emissions by approximately 20 per cent, when an upgrade to one of our furnaces is complete. The rebuilt furnace will be powered in part by oxyfuel technology drawn from our own onsite oxygen plant – in itself powered by renewable electricity. Such a reduction on fossil fuel use will move it into the top 10 per cent of energy efficient furnaces worldwide.

Oxyfuel furnace technology is one alternative. At our France-based Saverglass sites, our teams have successfully trialled a hybrid furnace which may be capable of running on 80 per cent electrical energy.

Orora has also been a market leader the adoption of renewable energy. Our Gawler site uses renewable electricity sourced from wind and solar generation assets based on long-term power purchase agreements.

Another important decarbonisation focus for glass manufacturers has been the production of lighter weight bottles. This reduces the amount of material used, which is more energy efficient, while it also lowers transportation costs, further reducing emissions.

Orora’s light-weight bottle for sparkling wine is approximately 15 per cent lighter while maintaining the same shape and dimensions. Modelling by our Saverglass team suggests bottle weight could reduce by up to 30 per cent. We’re also working in partnership with a global consortium, International Partners in Glass Research (IGPR) to explore the development of zero-carbon bottles. This is another exciting step in the ‘future-proofing’ of glass.

Circularity and recycling

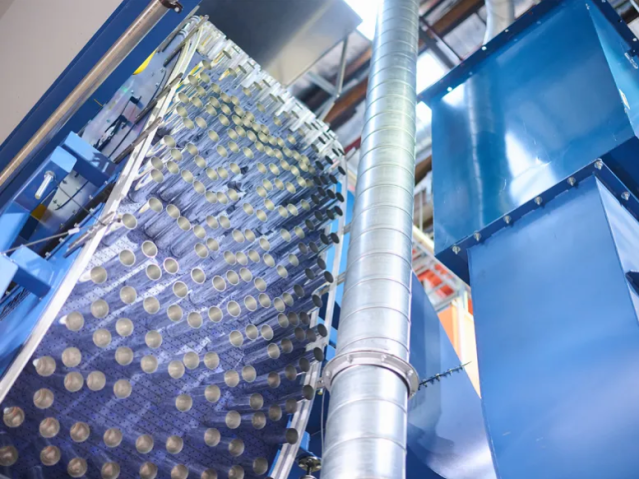

Increasing the use of recycled glass in the manufacturing process is also critical for sustainability and is a major priority for Orora. The more cullet (crushed recycled glass) we use in the manufacture of new bottles, the less raw material is required. Using cullet requires significantly less energy than raw materials, as it melts at a lower temperature, reducing the overall environmental impact of each bottle produced.

Orora invested in its own glass recycling facility to increase the amount of cullet we can access and use. The plant has capacity to produce up to 150,000 tonnes of cullet per year, which equates to more than 330 million wine bottles or 750 million beer bottles. This year, our new bottles have been made up of 50 per cent recycled content, and our target is 60 per cent next year.

Consumers themselves have a major role to play in the sustainability of glass bottles, through depositing used glass bottles at Container Deposit Schemes – a major source of Orora cullet.

Producing a superior glass packaging product that is increasingly sustainable will remain an Orora priority. While we’re pleased with our progress to date, there is still a lot of work to do in exploring and developing new technologies that help us reach a net-zero position as an industry. However, the work delivered so far is promising and as a result, the future for glass looks bright.