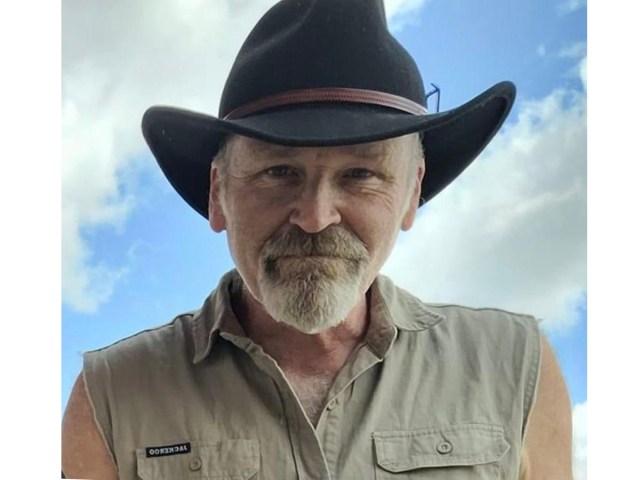

Auckland-based PrintLounge general manager Greg Daniel took to the recent ProPack Packaging Forum to discuss how the company’s latest technology investments are supporting its growth plans.

Daniel announced that the company recently installed an AB Graphic finishing equipment, with another unit on the way.

“Brands themselves were telling us of the importance of good finishing. We decided to go down the AB Graphic route with the Digicon. We never looked back from that point. It’s a great piece of equipment, the engineering is superb, the service is amazing, and the accuracy and speed of the equipment is fantastic,” he said, via Zoom.

“We’ve just purchased another unit from the Digicon Lite 3 Series, that will soon be on its way over to us.”

Modular in design, the AB Graphic Digicon can be designed to meet a business’ needs, enabling them to create a clear and competitive advantage.

PrintLounge is a family-owned business that has been in operation since 2000. It was known to be a sheet-fed operation up until 2016 when it purchased its first Komori H-UV press, following which it also moved into the LED-UV space.

Also, within that time, it upgraded its digital machinery and moved into the labels space.

“Now, we’ve ended up as a commercial packaging with digital printing company that also does roll labels,” Daniel said.

“When we first started in roll labels, we were only dipping our toes in this space and used a basic CMYK toner-based machine. But, we soon realised we required quite a bit more – we needed white, we needed a wider colour gamut.

“We did a lot of research and decided on the Durst Tau RSC 340 E LED label press with LED curing and the new Durst Hawkeye system in 2023.

“What it has done is changed the way we work here. The software drives that machine and within minutes, we have got ink usage for a quote, we’ve got the team in pre-press able to make colour correction or whatever else needs to be done with the click of a button.

“It’s amazing how fast that is, and that flows on to the actual machine itself. That has changed everything from the high resolution that it prints at, to the amazing white that it puts down, all at 50 metres per minute. And to think that we can still upgrade that to 80 metres a minute.

“All we are focussing on now is getting jobs out the door.”

The inaugural ProPack Packaging Forum would not be possible without the support from its sponsors:

Platinum Sponsor – Durst Oceania

Gold Sponsor – Cyber

Gold Sponsor – Miraclon

Bronze Sponsor – Hybrid Software

Bronze Sponsor – Kissel & Wolf

Bronze Sponsor – Koenig & Bauer