Flint Group has introduced a new whitepaper that closely examines the UV LED curing technology and the role of dual cure inks, as the adoption this technology gains momentum among narrow web printers due to its numerous benefits.

The whitepaper, tailored to assist printers and converters in transitioning from traditional mercury-based UV curing to UV LED systems, explores the rapid growth of LED curing technology and its significant impact on the narrow web printing sector.

With a focus on how sustainability, efficiency, and performance can work together, the whitepaper is a valuable resource for printers and converters seeking to stay ahead in the label printing industry.

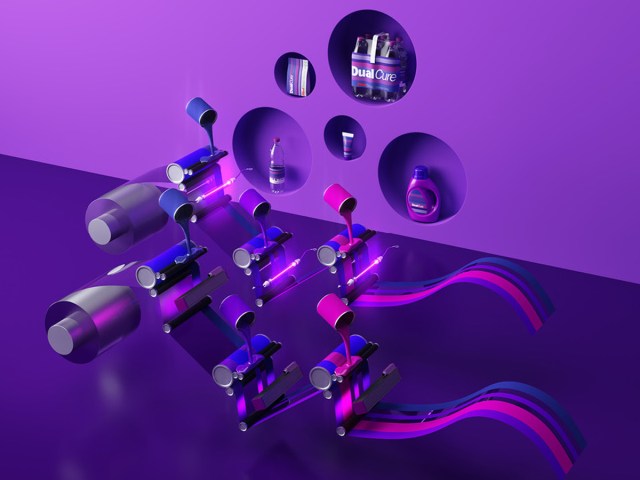

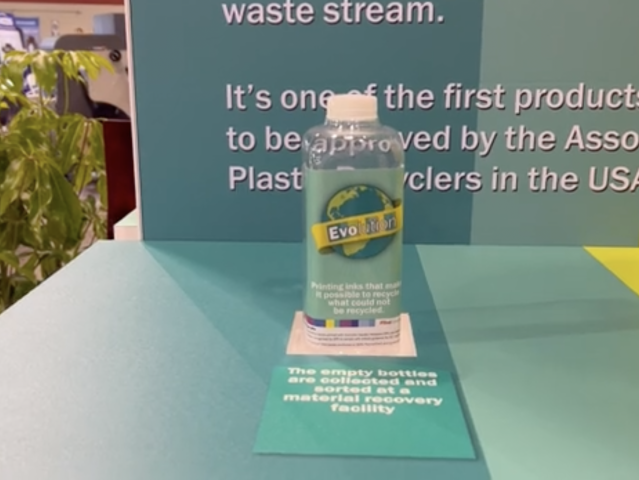

The whitepaper touches key aspects that make UV LED curing a game-changer for narrow web printers, including the energy efficiency, eco-friendly advantages, longevity and cost savings and a sneak peek into the EkoCure Dual Cure ink range from Flint Group.

Flint Group marketing manager for narrow web Anna Niewiadomska commented, “We pride ourselves on vast ink and coating expertise, but knowledge is meaningless if it can’t be shared for the benefit of the wider industry. That’s why we put such a key focus on developing industry whitepapers.

“In a market that continues to evolve dynamically, printers are experiencing increasingly tighter profit margins. Our whitepaper seeks to streamline the complexity and present the numerous cost and sustainability advantages of UV LED curing, which are of great interest to today’s printers. This guide draws upon Flint Group’s extensive ten-year expertise in UV LED technology development.”

The whitepaper is available for download from the Flint Group’s website.