Esko has taken to its Esko World 2025 event to launch several new advanced solutions designed to drive efficiency, sustainability, and profitability for converters and shorten time to market for consumer packaged goods brands.

Esko president Joël Depernet used the opening keynote presentation to officially unveil the raft of innovations that embrace cloud computing and artificial intelligence (AI) to deliver improved sustainability, third party integration, central data storage and greater efficiency in process and task management.

Kicking off this year’s packaging technology event in front of more than 500 packaging and labels converters, brand representatives, and packaging experts in St Louis, Missouri, Depernet detailed how the six new innovations address today’s fast-changing business environment and evolving regulations.

“In the face of mounting challenges for brands and their label and packaging partners, these latest introductions to the Esko ecosystem underline how we remain true to our aim of continuous improvement through innovation, developing technology solutions that address the growing business need to better connect people, processes and technologies,” Depernet said.

“As a long-term partner to our customers, we are committed to innovating to ensure our solutions empower and enable anyone using them in the packaging value chain to benefit from improved operational efficiency, quality and to more easily achieve sustainability objectives.”

The six innovations introduced at Esko World are:

• Esko Comply – a new, AI-powered artwork review and compliance checking tool that brings further quality assurance to the prepress process, available now to the pre-release community ahead of wide release in November 2025

• Esko WebCenter Go – a complete packaging management solution for small-and-medium-sized brand owners, available from September 2025

• Esko WebCenter Pack – delivering complete packaging management specifically for converters, available immediately following its global launch at Esko World

• Esko Print Clone – harnessing the power of AI in a new cloud-based colour matching solution that effectively reverse engineers a colour profile, minimising trial and error and speeding up colour matching, available worldwide following its launch at Esko World

• Esko Cape Prime – a new packaging-driven sustainability solution that helps converters successfully reach their own sustainability targets, available to the pre-release community

• Esko CDI Quartz – now available worldwide, a top-of-the-line addition to the market-leading family of Esko CDI and XPS plate imaging and exposing solutions. The Esko CDI Quartz delivers accurate and quality plates that reduce ink usage to deliver quality final print.

WebCenter Pack and WebCenter Go

Esko said WebCenter Pack and WebCenter Go are two targeted packaging management solutions specifically designed to boost brands and label and packaging suppliers’ efficiency and customer satisfaction.

Announcing the launch of the new unified communication platforms, Esko chief marketing officer Jan De Roeck said WebCenter Pack had been developed to address the needs of customer service representatives at packaging converters, while WebCenter Go was tailored for emerging brands’ in-house packaging production teams.

“With these two new innovations, we are broadening the functionality of our flagship WebCenter packaging management platform and bringing brands closer together with their packaging and label suppliers,” De Roeck said.

“WebCenter Pack enhances the job onboarding process at label and packaging converters with intuitive tools and seamless prepress integration that serves to boost productivity, reduce costs, and shorten lead times. Dashboards and reports provide valuable insights, while the affordable subscription model makes it accessible with minimal investment.”

WebCenter Pack aims to empower customer service teams to handle preflight checks independently, leading to quicker customer feedback and significantly reducing delays.

WebCenter Go enables growing brands to collaborate on packaging, eliminate errors, ensure quality, and go-to-market faster than competitors.

“Developed to meet the challenges faced by growing brands, WebCenter Go ensures packaging artwork is produced right first time, every time,” De Roeck said.

“From customisable checklists and colour accuracy verification to making version comparison quicker and easier, it enables teams to build approval workflows, proofread pack copy and check artwork compliance all in one place and right out of the box.”

Esko has today (5 June 2025) launched a powerful new tool that streamlines complex processes to help brands meet packaging compliance standards, dramatically reducing costly errors, reworks, and regulatory risk.

Esko Comply

Esko Comply offers an intelligent, automated way to validate critical components of product packaging and promotional materials, using customisable rules and AI to check labels and packaging for missing allergens, incorrect barcodes, FDA formatting violations, and other potential errors.

A new module for the WebCenter packaging management solution, Esko Comply fully integrates with the Esko ecosystem, empowering teams to maintain full creative control while embedding compliance checks directly into the design and approval process.

“With this new innovation, we are complementing our existing preflight tools and bringing additional quality assurance validation to our customers’ workflows,” De Roeck said.

“Ensuring artwork compliance has traditionally been a time-consuming and error-prone process, involving multiple rounds of manual reviews and approvals. With this latest solution, we’re transforming compliance from a bottleneck into a competitive advantage by helping teams identify and address issues early and move faster with confidence.”

The new Comply tool features a host of key capabilities, including:

- Automated compliance checks: Instantly scan artwork for alignment with predefined brand and regulatory guidelines

- Custom rule configuration: Tailor compliance criteria to suit specific industry regulations or brand policies

- Audit trail and reporting: Maintain a detailed history of checks, approvals, and changes for full traceability

- Collaborative review tools: Enable cross-functional teams to review, comment, and resolve compliance issues in real time

- Automated image measurement: Set the required dimensions of images and logos for image position, dimensions, colours, and brand elements, and AI performs all measurements without additional operator input

Print Clone

Print Clone is an advanced cloud-native colour matching software set to transform digital print production. Esko Print Clone leverages artificial intelligence and automation to enable digital press operators to replicate colours from previously printed packages with unmatched precision, regardless of the original printing process.

“Print Clone delivers high-quality results with minimal manual intervention,” De Roeck said.

“This innovation eliminates the traditional trial-and-error approach, significantly reducing manual interventions and accelerating job completion times for packaging and label converters.”

With Esko Print Clone, packaging and label converters can benefit from:

• Real-time adjustments: operators can instantly refine colours by uploading PDFs and using a spectrophotometer

• Quick measurements: replace tedious trial-and-error methods with just a couple of clicks

• AI-powered precision: advanced algorithms ensure colours match specifications perfectly

• Consistency across runs: maintain uniform colour across different substrates and print jobs

• Production-ready files: dynamically adjusted PDFs match original artwork seamlessly

“Once a PDF file has been drag-and-dropped into Print Clone, a spectrophotometer guides the operator to carry out a real-time colour comparison,” explained Jan. “The AI-powered algorithms then optimise colour accuracy to deliver a high-quality, colour-accurate output with minimal manual adjustments,” De Roeck said.

“By integrating Print Clone into their workflows, digital press operators can ensure consistent, high-quality results while reducing their environmental impact and operational costs.”

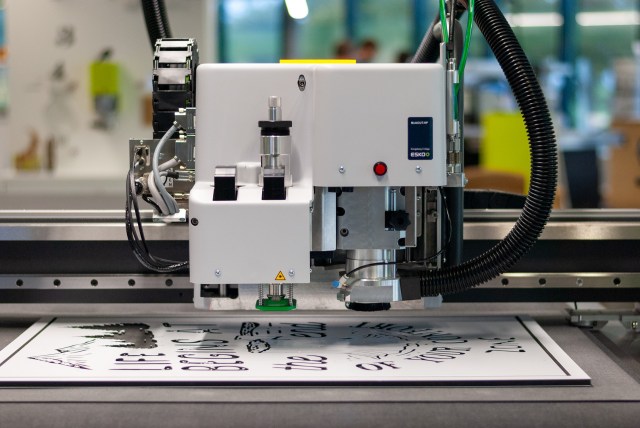

Esko Quartz

Esko Quartz, which was first introduced at drupa last year and “hailed as the pinnacle of flexo platemaking”, is now available for ordering worldwide with the first shipments expected by September.

The Esko Quartz ecosystem complements the Crystal ecosystem as a top-of-the-line addition to the Esko digital flexo solutions portfolio, offering a dual optics system that supports both legacy and forward-looking flexo platemaking with optimised Quartz Screening.

New Quartz optical technology enables users to image higher frequency surface structures at 2000lpi (Q-Cells) with an imaging resolution of 4000ppi.

The Esko Quartz ecosystem is compatible with solvent and water-based inks – delivering an increased density of up to 0.7 for water-based inks.

The new Esko CDI Quartz delivers:

• Smoother ink coverage, better contrast and deeper shadows

• Increased ink density by up to 0.7 to achieve new levels of depth

• No pinholes or negative artefacts

• Negative small elements stay open longer and dot-bridging in screens is eliminated, keeping fades and pictures cleaner

• Higher ink laydown enables the usage of finer anilox rollers, and thus brilliant solids in combination with fine highlights and fades to zero

• Reduced ink usage and compatibility with water-based inks make sustainability goals achievable

The new Esko Quartz is available as an ecosystem solution including the CDI Quartz, the XPS, Quartz screening and premium care plan. It is now commercially available for the plate sizes 4835, 4260 and 5080.