This article first appeared in the February 2025 issue of ProPack.pro, authored by Patrick Graber, narrow-mid web printing and converting marketing director at BOBST.

Label converters face challenges from many different directions that directly threaten the profitability of their businesses. However, despite pressures on price and severe labour shortages, combined with the need to adapt quickly to new market trends while delivering high quality labels, there are still opportunities to grow for those ready to embrace the world of digitalisation, automation, and connectivity.

Following a contraction of the label market in 2023, volumes returned to more normal levels in 2024, according to Smithers’ The Future of Printed Labels to 2029 report. Even better news, the report predicts a compound annual growth rate (CAGR) in value of 4.6 per cent, which is equivalent to 4.4 per cent in volume terms. But competition is fierce, and costs are rising, meaning converters must implement solutions that simplify label production to capitalise on this growth and safeguard profit margins.

Mitigating the skills drain

Label converters operate in a dynamic market that requires a high level of agility to respond to brand owners’ demands for rapid turnaround, shorter run lengths, and excellent quality. However, the industry faces a growing shortage of skilled operators and a knowledge transfer gap due to fewer young people entering the field. Without experienced staff to run the presses and operate the finishing machines, the industry must look to technology to maintain standards.

One of the major pain points compounded by the skills drain is ensuring colour consistency – not only over time but also across different printing technologies and applications. Meanwhile, the increasing emphasis on sustainability, including waste reduction and the use of new eco- friendly materials, adds a significant dimension to an already complex situation.

We are seeing the industry addressing these issues from a product and process point of view. The main trend can be observed in digital printing with a move towards automated inline processes. Here, end-to- end or ‘all-in-one’ workflows are gaining ground. Already in use by most medium to large converters, these advanced integrated solutions are capable of producing ready- to-ship labels in one pass with a single person operating the entire line.

Digitalisation on the flexo front

Narrow web flexo technology is also being further optimised by incorporating higher levels of automation and digitalisation to improve efficiency and minimise waste, regardless of the machine operator’s skills or qualifications. It is important to note that flexo remains the primary technology for label production in the short- to medium-term, accounting for nearly 40 per cent of the market volume in 2023, according to Smithers.

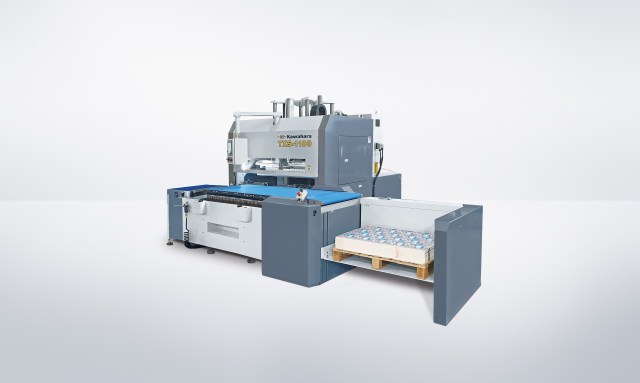

Operating old flexo presses is an art in itself, so with the number of experienced operators falling rapidly, companies must move to more automated solutions to ensure output quality. BOBST is already well regarded for its highly automated inline flexo presses with innovative features such as DigiFlexo and DigiGap ensuring automatic register and pressure adjustment, automatic job change, and high-performance semi-rotary die-cutting with automatic die-plate change, amongst others.

Mastering digital inline operation

The transition to all-in-one operation, where labels are produced on one machine that incorporates digital and flexo printing, embellishment, die-cutting and quality control, is ramping up, driven by the need to deliver exceptional quality at speed with the lowest possible amount of waste and at competitive costs. Configurable with any number of value-adding modules, the Digital Master modular platform from BOBST gives converters the capability to produce a much wider variety of superior quality products. Complex applications, such as multi- layer labels, highly embellished labels, to name a few, can be much more effectively produced on these presses.

At BOBST, we are focusing our efforts on the development of automated, digitalised and connected solutions. The aim is to provide the highest ease-of-operation by leveraging a closed loop workflow infrastructure through BOBST Connect, the cloud-based platform created for a seamless entry into the data-driven world.

This is the BOBST vision – a fully connected workflow from job PDF to final twin PDF, where with every job we print, we learn more to continually improve the way we work.

Label production in the future

Looking ahead, we foresee that labels will increasingly be produced in a single pass due to the trends discussed above. BOBST’s inline flexo and all-in-one presses are designed to future proof our customers to ensure they stay ahead of the curve and adapt to evolving market needs with confidence.

Further ahead, smart factories are on the horizon. While for the moment the concept of fully automated label production is visionary thinking, we are closing the gap step by step. Technology has reached a high standard, the next level in innovation lies in optimising the processes, streamlining operations and connecting the dots between different workflow steps.