Under the motto ‘Simplifying label production’, Bobst has brought a range of equipment to Labelexpo Europe 2023 to demonstrate its leading innovation in labels and flexible packaging production with two main production lines in focus.

Bobst believes that the commoditisation of label production by minimising human interaction in the entire production flow is the answer to all the challenges converters face.

Human errors and inefficient workflows are costly and incompatible with commodity production, where thin margins require effective competition. Sustainability is necessary to reduce the environmental impact of packaging.

The company is spearheading digitalisation, automation, connectivity and sustainability in packaging production with a portfolio that includes flexo, digital and all-in-one presses for the widest variety of applications.

Bobst Narrow mid-web general manager and global head Matteo Cardinotti said, “Innovation in the label industry is shown at its best at Labelexpo. New manufacturing technologies continue to support opportunities that simply were not available before and we see more of that at the 2023 edition.

“Bobst welcomes visitors to the booth to show them how we have the best solutions to the challenges they face in today’s market and for the future and how we can help create new business opportunities.”

The company is showcasing the Digital Master Series, which features a built-in digital front end (DFE) connected to a fully automated printing module to independently handle calibration and cleaning routines.

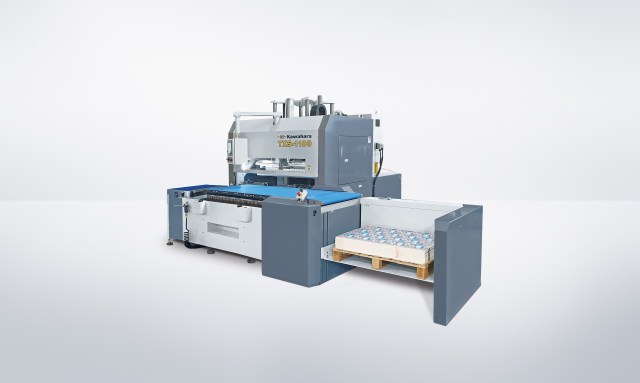

It connects to flexo modules equipped with features such as automated pressure and register settings. For finishing, Bobst showcases the latest automated and easy-to-operate cutting solutions.

Based on Bobst Accucheck technology, the new quality control system ensures meticulous label inspection, from colour stability to print errors. If any mistakes are detected, the machines’ prompt action minimises waste.

According to the company, the Bobst M6 press also showcased at Labelexpo, is the most automated in-line flexo press on the market. A key feature is the entirely automatic flexo job changeover possible thanks to the patented Bobst V-Flower technology.

In combination with DigiFlexo registration, pressure adjustment, and Bobst oneECG colour management, changing a job can be performed in under one minute with minimal ink, material and electricity waste, making it the most sustainable conventional solution.

In addition to Bobst gravure and CI flexo presses, the Master M6 is suitable for mainstream short-to mid-run flexible packaging and shrink sleeve applications.

Bobst also showcases various sustainable options at its booth, including AD LinrSave solution, new substrates, most waste and energy-efficient conventional printing solutions, quality control systems like Accucheck and automation systems like DigiFlexo.

These advancements reduce human errors, minimise waste, and contribute to a more environmentally friendly production process.

The company believes that by 2030, many labels will be made from recycled or biodegradable materials. New inks, energy-efficient printing processes, and reduced waste generation will become industry standards; therefore, Bobst is actively working towards them.

“Labelexpo has always been a major milestone for Bobst and converters. For this edition, together with our partners, we continue to shape the future of label production. We take you across all the steps required to make labels better and more sustainable than ever,” Cardinotti concluded.