This article first appeared in the April 2025 issue of ProPack.pro magazine.

Victoria-based Affinity Print has bought two folding carton machines from Graffica, strengthening its in-house end-to-end packaging capabilities.

The company, which recently also celebrated 50 years in operation and moved into a new, larger facility, invested in an 850 CartonFold folding box gluer and a 1060 fully optioned Century die cutter from Graffica, offering clients high-end packaging solutions.

Affinity Print owner Steven Todisco said “The move to a bigger premises allowed us to execute on our strategy of bringing our production in-house. This involved the purchase of the 850 CartonFold folding box gluer and a 1060 fully optioned Century die cutter.

“Affinity is now one of the few printers in the country to run a full in-house packaging solution, with foiling, embossing, coating, and UV capabilities. What we can offer the market is of the same level, if not better, than some of the ‘big boys’, which is fantastic for a family-run company.”

Todisco said he chose the machines for their automation, optimised speed, accuracy, and diverse range of functionalities, adding that the units work seamlessly with the company’s other machines.

“The machines have allowed us to boost our productivity multifold. Our turnaround times have also multiplied, allowing us to take on more jobs than before,” he said.

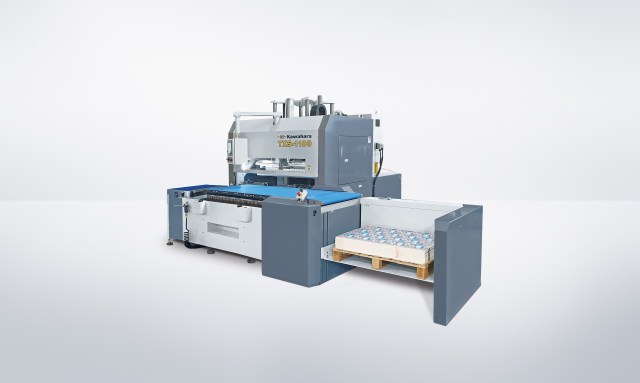

The 1060 fully optioned automatic flatbed Century die cutter is known for its die cutting, stripping, and creasing of high-end coloured cardboxes. Equipped with the latest Siemens PLC technology, a top feeder system, and a high running speed, the machine is highly efficient.

The machine, which is built for quick set- up, safety, wide stock range, and reducing damage to print sheets, can handle solid board (90gsm to 2000gsm) and corrugated board of single flute up to 4mm.

A pneumatic lock up and centerline system are used for a fast-cutting die set up and job changeover. Precise control over the die cutting process is achievable on the electrical control system.

It also has a full stripping function (triple action stripping system and lead edge waste removal device) to save on labour costs and shorten delivery times.

With a maximum mechanical speed of 7,500 sheets per hour, it also has a sheet blowing system and brush system at its delivery section for solid board perfect collecting. “The die cutter is high-end equipment. As Affinity Print generally does high-end, short-run work, its fast turnaround times meets the company’s requirements,” Graffica director Neil Southerington said.

As for the 850 CartonFold folding box gluer, it features speeds of up to 500m/ min. It allows for a wide stock range – with 200gsm to 800gsm cardboard and corrugated board.

Its full configuration includes a pre-fold unit, straight line, crash-lock bottom, and four- and six- point corners. Optional additions include: a pre-feeder, pre- crease, braille system, CD boxes, bump turn, auto-set and job recall functions, plasma device, grinder with dust extraction, cold glue system, hot glue system, tape application, and box packer.

“The 850 CartonFold folding box gluer’s capabilities covers the whole gamut of box folding. It’s a very fast machine and adds a lot of value to Affinity Print’s packaging needs,” Southerington said.

“Graffica is thrilled to have Affinity Print as a customer, especially in such a significant purchase from a medium-sized company. It’s very well-established in the market and plays in the high-quality space. Affinity Print’s investment in machinery from Graffica speaks volumes about our offerings as it’s a testament to the quality of our products and service.”